This article was also published in Issue 41 of The Expert Witness Journal. Click here to read more about their publication and see other issues.

Forensic investigations into the causation of vehicle fires may be considered, by some, to be a dark art. This could be in part due to the lack of visual indicators available that prove useful when investigating property fires, such as patterns of fire damage. Vehicles also have numerous combustible fluids stored in a confined space, the release of which can produce localised ‘fire loading’ during a fire. Therefore, the greatest area of burning might not necessarily be at the origin of the fire. Furthermore, the inexorable growth in entertainment and connectivity technology has resulted in increasingly complex electrical circuits in modern day vehicles. This can add to the difficulties establishing the cause of a fire arising from an electrical incendive fault (i.e. an electrical fault that can initiate a fire).

VEHICLE FIRE STATISTICS

According to Government statistics, there were a total of over 17,500 vehicle fires in the UK in the past financial year (2020/2021); remaining unchanged for the past 10 years[1].The data collected is separated into accidental and deliberate causes, with accidental fires plateauing at around 7,000 per annum.

However, unlike property fires, vehicle fires are rarely investigated by the Fire Services, so the cause of the fire may be recorded incorrectly, especially because some electrical incendive faults can initiate a fire in a vehicle even when it has been parked and switched off for some time: The hot components in the engine compartment cool quickly after the engine is switched off, which means that:

- There are no hot surfaces present to ignite escaping combustible fluids, such as fuel, engine, or hydraulic oil

- Neither the circulating pumps associated with the lubricating and power assistance systems, nor the supply pumps associated with the fuel system, are operating, which minimises the risk of an escape of fluid occurring

However, when an engine has been switched off, even for a period of time, some circuits remain energised including key CAN (Controller Area Network) control modules, the cooling fan, alarm, and interior lighting circuits, all of which can initiate a fire. Therefore, without appropriate investigation, it is possible that the total amount of accidental vehicle fires is greater than the recorded figure.

The Driver and Vehicle Standards Agency (DVSA) registers the number and type of vehicle recalls that manufacturers must undertake. In the past three years (within a typical warranty period for a vehicle), there were over 300 recalls that related to a risk of fire, caused by either electrical or mechanical failures. However, the DVSA recall list does not include any technical bulletins that manufacturers issue in-house, which are not available in the public domain. Therefore, there is the potential for further issues with current models of vehicles that could result in fires or fire risks.

This article concentrates on vehicles with 12-volt system architecture, and will discuss some of the common electrical incendive faults that can occur in these vehicles; including resistive heating faults initiated by a poor connection, tracking faults, and fretting wear.

POOR CONNECTIONS

A poor connection exhibits a higher resistance to the flow of electrical current than normal. When a current is drawn through such a connection, the connection heats up. This heating promotes the formation of an oxide layer, which then further increases the resistance of the connection. This cycle continues and the increased temperature, if hot enough, can lead to the ignition of nearby combustible materials. Many terminations are made during the production of a vehicle. These terminations require a specific torque (turning force) applied, so that the connections are secure. If they are under-torqued, then this can lead to a poor connection, and potentially a fire.

TRACKING FAULTS

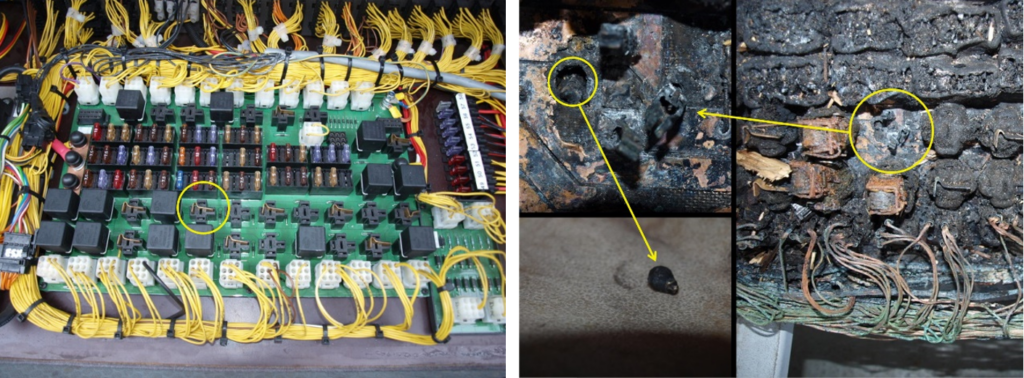

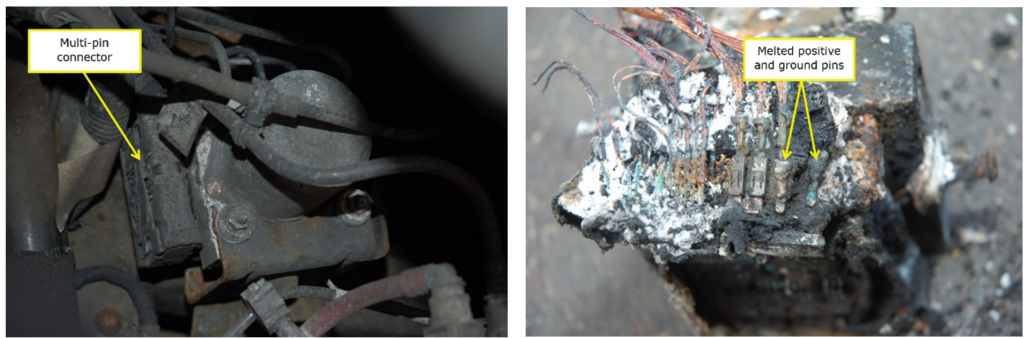

A tracking fault can occur due to either mechanical damage or contamination of insulation, such as from water ingress that bridges terminations of differing potentials in a device or connector. When the insulation breaks down, a fault current flows. Heat from the flow of this fault current carbonises the surface of the insulator along the path, or track, of the fault current. As carbon is conductive, the magnitude of the fault current increases, leading to further heating and ultimately ignition.

In this instance, the orientation of the multi-pin connector was such that it allowed the ingress of water. The moisture caused a tracking fault, which had bridged the live and ground pins within the ABS multi-pin connector and caused melting to occur. This vehicle was subject to a recall campaign for this issue.

FRETTING WEAR

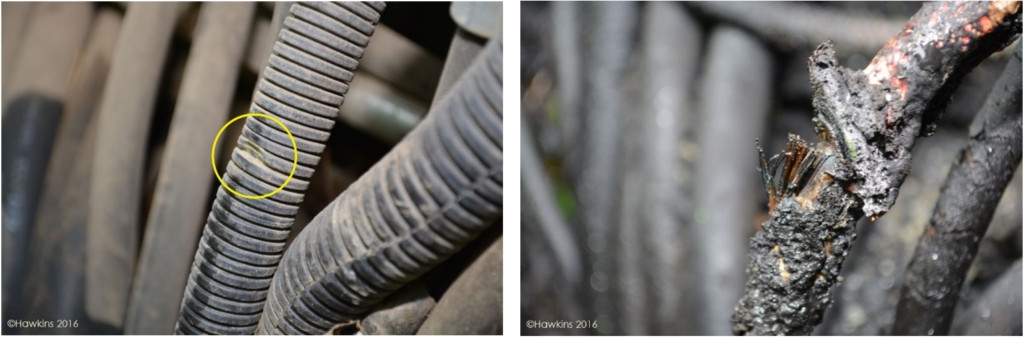

Fretting wear occurs when two contacting surfaces experience relative motion, causing localised damage. Where this becomes a concern in the manufacturing of vehicles, is the routing of wiring harnesses. If fretting wear occurs to an energised wiring harness, the insulation of the wiring becomes compromised, and this can lead to arcing damage. Arcing occurs when conductors of differing electrical potentials come into contact and create a short circuit. This in turn can lead to the ignition of the surrounding combustible materials. Below are two images of the poor routing of a supply cable that connected the battery to the starter motor in a telehandler.

SUMMARY

Much is done in the automotive industry to stop electrical incendive faults occurring, by rigorous testing and increased scrutiny in internal quality control. However, Hawkins fire investigators still identify these mechanisms as causes of vehicle fires.

With the car market trend heading toward a fully electric vehicle powertrain, one wonders whether the propensity for incendive electrical faults will increase, or whether, owing to the risks inherent in managing high voltages, there will be more attention paid to rectifying these failure modes?

ABOUT THE AUTHOR

Luke Collins started his career investigating causes of vehicle fires, having carried out over 300 investigations by the time he joined Hawkins in 2014.Since then, Luke has continued to investigate these cases, but has expanded into investigating fires and explosions in domestic and commercial properties, and on ships.