Glasgow series – BLEVE’S: The Hidden Dangers of Back Boilers

The hidden dangers of back boilers: Outlining the risks with domestic back boilers, and incorrect decommissioning can result in catastrophic damage

Glasgow Series – Over-Fired Air (OFA) in Industrial Boilers

Webinar: Over-Fired Air in Industry Boilers. Paul covers how pollution control technology can cause a loss of steam and/or power generation.

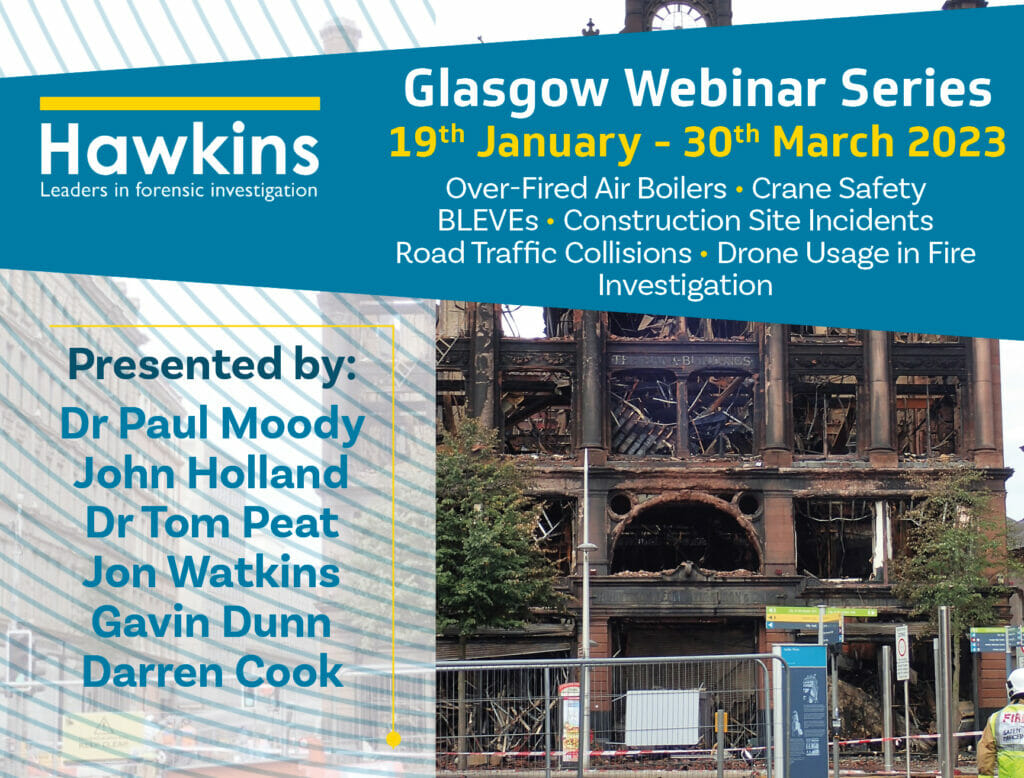

Hawkins Webinars: The Glasgow Series

To kick off Hawkins’ educational content for 2023, our Glasgow Office has created a series of webinars covering engineering, fire investigation, and road traffic collision topics. Read a summary of each webinar and register below. CLICK HERE TO REGISTER Over-Fired Air (OFA) In Industrial Boilers Presented by Dr Paul Moody 19th January 2023 at 9:30am GMT This webinar will discuss how pollution control technology can cause a loss of steam and/or power generation. Crane Safety: Not Just Torquing Nuts! A Review of the Carol Anne Crane Collapse Presented by John Holland 2nd February 2023 at 9:30am GMT This webinar will review a fatal crane accident on the Carol Anne workboat in 2015 including: The mechanics of the incident The complexity of crane mounting The benefits of investigating at an early stage BLEVEs: The Hidden Danger of Back Boilers Presented by Dr Tom Peat 16th February 2023 at 9:30am GMT This webinar will show the risks associated with domestic back boilers, and how environmental factors and incorrect decommissioning can result in catastrophic damage to property. MEWPs on Construction Sites: A Lower Risk Option Presented by Jon Watkins 2nd March 2023 at 9:30am GMT This webinar will look at the types of Mobile […]

Hawkins Welcomes Mechanical Engineer Ian Jeavons

Hawkins welcomes mechanical engineer Ian Jeavons to our Leeds Office.

Hawkins Welcomes Mechanical Engineer Natasha Moore

Natasha is now an Associate based in our Bristol Office and will be a great addition to both the mechanical and materials engineering teams at Hawkins.

Hawkins Welcomes Materials Engineer Giuseppe Scatigno

Hawkins welcomes chartered materials engineer Dr Guiseppe Scatigno to our Bristol Office.

Philippa Moore

Philippa graduated from the University of Cambridge with MA and MSci degrees in materials science and metallurgy. She subsequently stayed at Cambridge to gain her PhD, researching the microstructures and properties of laser and laser/arc hybrid welds in pipeline steels, a project supported by industrial partner, TWI Ltd. Philippa then spent 18 years working at TWI Ltd, and developed an international reputation in fracture toughness testing, and engineering failure investigation, often of welded steel structures, through her project work and consultancy. In her last six years at TWI she was a Team Manager, her roles included responsibility for a team of engineers who delivered fracture toughness testing services for TWI. She has also carried out projects related to fracture tests in corrosive environments and hydrogen embrittlement of steels. She has published over 45 conference and journal papers on her academic research, and on topics supporting her involvement on British and International standards committees for fracture testing. Philippa was herself the industrial supervisor of five PhD students and four MSc students from 2013 to 2019 working on fracture-related topics. An inspirational and respected technical expert, she is an enthusiastic and experienced presenter to both technical and non-specialist audiences on topics related […]

Ian Jeavons

Ian graduated form the University of Manchester in 1996 where he studied mechanical engineering. After graduation, Ian joined IMI Plc on a graduate programme which gave him a broad range of manufacturing experience in the production of water heating systems and pneumatics. Later, Ian joined the research division of IMI Cornelius where he gained experience in the development and testing of a commercial water treatment system. Ian then became the global coordinator and technical support for the system’s field trial where he continued to develop data management and analysis skills. Ian joined New House Textiles in 2001 to run the engineering department during the development and testing of a weaving technology system. After a sabbatical, travelling the world, Ian returned to the UK to start a new career teaching engineering apprentices. During this time, Ian gained a Post-graduate Certificate, having studied advanced manufacturing techniques and aerospace materials, and researched the effect of temperature on carbon fibre composite during machining for his dissertation. Ian continued his academic studies and in 2021 gained his EngD by using a laser tracker to measure, model and correct the positional accuracy of an industrial robot for machining operations. His research was sponsored by Hexagon Manufacturing […]

Giuseppe Scatigno

Giuseppe graduated with a 1st Class Master’s Degree in Materials Science and Nuclear Engineering from Imperial College London. During this period, he worked at the International Atomic Energy Agency (IAEA) in the Incident and Emergency Centre, performing radiological dose calculations, following the Fukushima nuclear disaster. He completed a PhD, researching electrochemistry and corrosion, where he focused on environment-assisted corrosion phenomena, working closely with several nuclear utilities across the world. Giuseppe also spent time in Japan working on the development of Gen III+ reactors at Hitachi-GE Ltd. Giuseppe’s PhD work required the extensive use of state-of-the-art microscopy techniques, experimental traditional techniques, as well as computational, mathematical, and analytical methods. After completing his PhD, Giuseppe worked as a Research Associate for Imperial College, sponsored by EDF Energy, to study stress corrosion cracking resistance of dry cask storage units designed to be used for the interim storage of spent nuclear fuel. Giuseppe was then employed by EDF Energy, where he worked as a Corrosion Engineer and Chemist. Giuseppe worked closely with power generating stations before becoming the lead on water cooling systems and interim spent fuel storage. Giuseppe defined the chemical inhibitors regimes and corrosion monitoring systems to ensure the appropriate management of […]

Gerald Deshais

Gerald completed his PhD in Materials Science at the University of Cambridge in 1999, where he investigated the resistance of 7XXX alloys to stress corrosion cracking on behalf of Péchiney (now part of Rio Tinto Alcan).

Italiano

Italiano