Composites

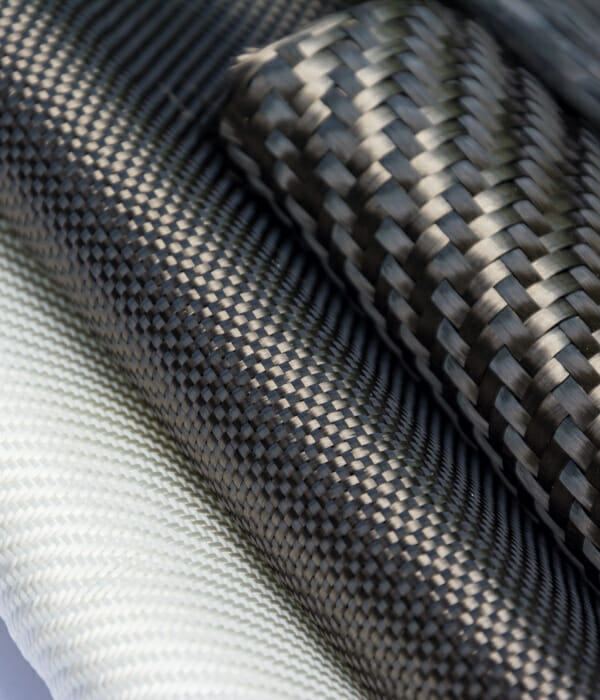

A composite material is any multicomponent material that contains two or more distinct constituents or phases, i.e. it is made from a combination of two or more different types of constituent material. Perhaps the most familiar examples in modern engineering are glass or carbon fibre reinforced plastic (GFRP or CFRP).

Whilst ubiquitous in nature, the application of engineered composite materials has become increasingly more widespread since the mid-20th century. More recently, rather than being limited primarily to the aerospace and marine industries, composite materials have found uses in all manner of everyday applications in a variety of domestic, commercial and industrial settings. Typically, they are still used in components that require high strength and rigidity, but with minimal weight, although in recent years they have also become increasingly popular for their aesthetic properties.

The purpose of a composite material is to optimise the individual component properties by the process of combination. For example, in GFRP and CFRP, high-strength fibres are combined in plastic matrices to create a strong, lightweight engineering ‘composite’ material. These materials are now commonly used in the automotive and marine sectors, but also in applications such as pipework, sporting equipment (e.g. bicycle parts and tennis racquet frames) and increasingly so, medical prosthetics, athlete’s running blades being probably one of the best-known examples.

Composite Materials Failures

Even the most technologically advanced materials can fail, whether through environmental effects, poor design, or manufacture, or due to extraordinary and unforeseen events. The sudden and unexpected failure of a composite material can, and often does have catastrophic results, such as the collapse of fork on a bicycle or the rupture of a pressure vessel. When investigating the failure of a composite material it is important to understand why that particular material was chosen in the first instance, how the different component parts have been, or should have been combined to maximise the resultant properties of the material, and how those components are likely to behave in the chosen application and environment.

If you are dealing with the failure of a component or a structure made from a composite material, you want to know what has caused it and how to prevent the same thing from happening again in the future, you need a forensic investigator. Hawkins can provide an expert who is familiar with all aspects of a case and can offer clarity and answers to your questions.

WHY APPOINT A FORENSIC INVESTIGATOR?

We have the technical knowledge and experience to tell you why a composite material component or structure failed, and not just what caused it.

- We have an in-depth knowledge of the regulations, guidance and best practices that should be followed during manufacture, assembly and/or installation of a composite part.

- We are familiar with the various materials that are combined together in composite materials (e.g. epoxy polymer and carbon fibres), the processes that are used to combine them and the expected properties and characteristics that they should have.

- We review working practices and methodologies to identify areas at a high risk of a fault.

- We offer guidance and/or help you define and develop good working procedures and practices to reduce the risk of incidents occurring.

- We provide you with the answers you need to determine why an incident occurred and so assist in repudiation/cover decisions and fraud identification.

- Our experts are knowledgeable in a wide range of areas and can investigate all aspects of composite material’s failure, meaning that you will probably only need to instruct one expert, rather than several.

- We have good working relationships with laboratories and knowledge of the appropriate test procedures to investigate a composite material failure.

- We will help you to determine if an incident could have been avoided.

- Our reports are purposefully written to assist clients in either preventing such failures from recurring, to assist insurers to validate and potentially subrogate claims and/or to consider recovery claims against a culpable third party.

- We support subrogation/recovery efforts.

- We help you to make decisions regarding where legal responsibilities/liabilities lie.

- We help you to defend wrongful claims.

- We produce reports suitable for Court and litigation.

- We provide consultancy advice to prevent similar events happening again in the future.

- If removing a risk entirely is unavoidable, we advise on steps to take to mitigate the risk and reduce the potential damage resulting from an incident.

- We advise on inspection, servicing, maintenance and repair regimes.

Examples of Typical cases

If you would like to know if we can help, please fill out our enquiry form or give us a call for a free consultation. The list below provides a few examples of cases which we investigate regularly or have investigated in the past.

- Premature failures of structural parts.

- Sudden/catastrophic failures of composite components.

- Part failures from bicycles, vehicles, aircraft, marine craft and domestic items.

- Composite reinforced pipe and hose failures.

- Poor/incorrect design or structural planning, leading to unsuitable parts.

HOW DOES HAWKINS INVESTIGATE COMPOSITE MATERIALS FAILURES?

1

Consultation

Hawkins’ investigators have long and wide experience of investigating such failures, through material characterisation, mechanical properties measurement and forensic analysis of the circumstances surrounding failures. We like to speak to you before we conduct any work, to establish how we can add value to the case. These discussions help us to understand your requirements, as well as determining how much information is already available, including for example, service records, first-hand witness accounts, photographs, and videos. We are also happy to provide you with an estimate of the cost of conducting a forensic investigation.

2

Inspection

If required and with your agreement, we will arrange to visit the scene to inspect the parts, item or location of the failure. Wherever possible or appropriate, we will retain faulty parts for examination in our laboratory where we utilise techniques such as optical, digital and electron microscopy to study failures and provide answers to why composite materials fail. Composite materials often also benefit from non-destructive scanning techniques, which can identify weakened or damaged areas of a component and we have experience of planning such analyses at external partner laboratories.

3

Conclusion

Once our investigation is complete, we will discuss our findings with you and prepare a report containing a detailed account of our investigation, conclusions, and where appropriate, recommendations for further work or advice.

Related areas of expertise

Glass & Ceramics

Hawkins can determine the cause of failure of ceramic and glass products which can often lead to personal injury, structural damage, loss of earnings.

Plastics/Polymers

Polymers, or plastics as they are more commonly known, are used in all aspects of modern-day life: from pipework to paint coatings, textile fibres to automotive components and adhesives to hot water bottles. Plastics are imbedded into our way of life, and failure of these materials can lead to personal injury, escapes of water, loss of earnings, to name just a few outcomes.