Contamination, the presence of a foreign material, can occur following an insurable event, such as a fire, escape of water or storm damage. Contamination of a building or area often represents a large proportion of the overall financial loss of the incident. As such, it is key to identify the extent and nature of the contamination, so that the appropriate actions can be taken to reinstate and minimise costs arising from both the restoration work and from business interruption. A rapid and independent assessment of the problem can, therefore, result in a significant saving to the insurer.

Combustion Products

One of the most common instances of contamination that Hawkins deals with is soot contamination following a fire. The chemical composition of soot and fire debris depends on the type of fire and the conditions during the fire. For example, smouldering fires generate large quantities of tarry products, such as polycyclic aromatic hydrocarbons, that coat surfaces in a ‘sticky’ brown substance. Fuel rich fires, i.e. when air (oxygen) is the limiting factor in combustion, for example, a fire in a sealed room, tend to produce more soot and incomplete combustion products.

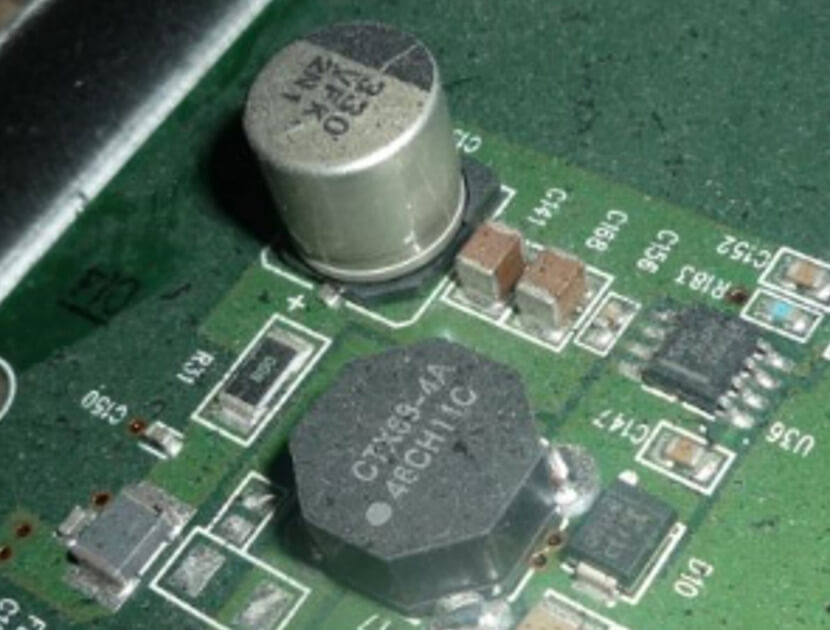

Some of the combustion products can be corrosive owing to the combustion of chloride-containing compounds. The classic example is the combustion of polyvinyl chloride (PVC), which is present in most fire scenes because many domestic and industrial wiring insulation comprises PVC. During combustion, PVC evolves hydrochloric acid up to around 50% of the weight of the material burnt. This means that the soot particles and other products are acidic. The acid reacts with materials, such as metals, and can result in rapid post-fire corrosion and degradation of metallic and other surfaces. It is also electrically conductive. This has implications for electronics, which can be seriously damaged by only small quantities of this type of soot.

Hawkins uses a method for detection of surface chloride concentrations that is fast and accurate, and gives on-site results, which allows for immediate identification of at-risk equipment and, potentially could reduce the size of the loss by early intervention. It is also useful for discriminating between different sources of dust such as whether the dust is a result of the fire, or whether is it ‘normal’ dust. Being able to determine the difference is particularly useful in industrial settings.

Odour

The typical smoky odour arising from fires is caused by a complex range of volatile and semi-volatile compounds. Those compounds present an issue because they can absorb into porous materials and, because they are no longer on the surface of the material, they are then difficult to clean. Examples of those porous materials include:

- fabrics, such as clothing;

- foams, such as in office chairs;

- packaging materials, such as cardboard boxes.

In all cases, zero odour or taint, i.e. the pre-incident condition, is the end goal of any decontamination work. Hawkins will assess the condition of stock/packaging and establish if it is usable/sellable and identify ways by which all fire-related odours can be removed, in order to reinstate buildings and contents to a pre-fire condition. How we do that or what might be salvageable (from ventilation, fogging and/or cleaning versus removal/disposal) might differ depending on the type of property and stock. On occasion, I have dealt with cases in industrial settings where some residual odour was tolerated in order that production could be re-established sooner.

As odour compounds tend to be volatile or semi-volatile, the strength of the odour will decrease over time as the compounds evaporate, or react with the environment. An example of this would be freshly ground coffee vs coffee that has been opened for some time.

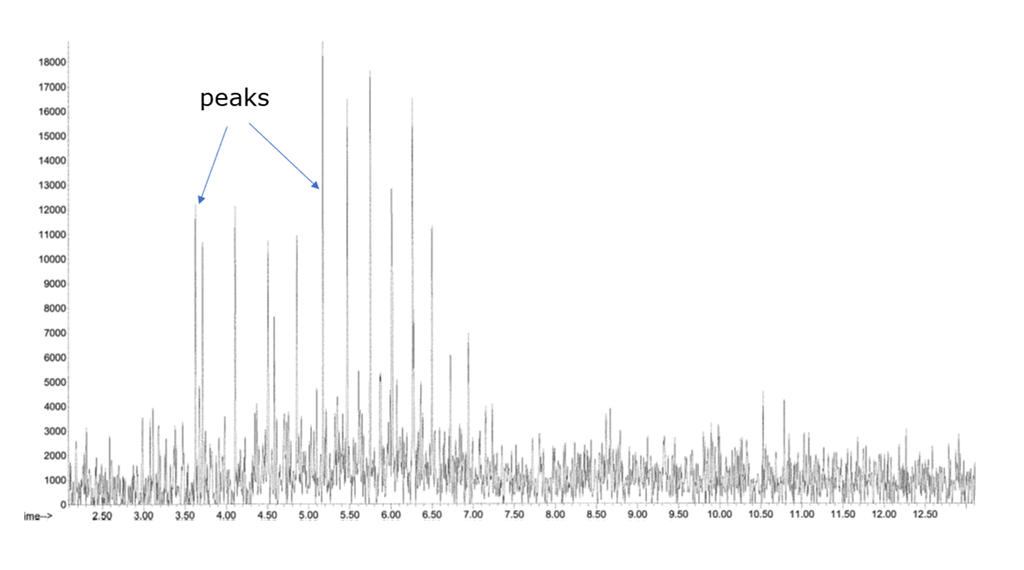

Odours are difficult to identify by normal analytical techniques. The human nose is extremely sensitive to odours and to some chemicals and is far more sensitive than analytical instrumentation. Ethanethiol, which is the additive in gas to give it the distinctive odour that we all recognise as gas, is a classic example of this. It is detectable to a person at better than one part in 2 billion, which is very difficult to test for using normal analytical techniques. However, when analysis for a specific chemical is required, for example, in the circumstances of a chemical spillage, there are some ways to increase the sensitivity of analysis, such as absorption onto an air sampling column to concentrate the chemical. Hawkins is experienced in air sampling of this type and in interpretation of the specialised analytical data resulting from the analysis.

Water

Contamination also commonly occurs following an escape of water, both due to the water itself and due to problems resulting from the long-term presence of water. It is my experience that escapes of water are often as damaging to a property as fire. Potentially both are combined; a small fire in a house that might not result in significant damage could be extinguished using water which then results in other problems in the property.

The damage to the property and the resulting contamination issues will depend upon the source of the water. For example, water escaping from a drinking water pipe presents a different set of problems to that of a leak from a soil pipe.

Water ingress to electrical equipment can lead to tracking faults or short circuits, resulting in damage to the equipment. These problems may take time to develop. Although pure water is not significantly electrically conductive, water almost always incorporates dissolved salts, which become concentrated as water evaporates. This can result in a fault that develops days or weeks after the initial event that led to the water ingress.

Silt, for example, from flood water can lead to abrasion of surfaces, such as, within bearings.

If the source of water potentially contains sewage, i.e. floods from sewers overwhelmed by rainwater, or a leak from a soil pipe, then sewage contamination can be identified (and distinguished from other sources of water), by sampling for the presence of specific bacteria. This can allow the appropriate remediation technique to be used. This can range from simple drying vs washing with anti-bacterial compounds.

Mould

Water ingress often results in the growth of moulds. Moulds are one of the structures that true fungi can form. The fungi reproduce by forming microscopic spores that are carried away by air currents. As such mould spores are everywhere. The monitor on which you are reading this article will be covered in spores waiting for the right conditions to start growing. If the surface remains damp (or of sufficient humidity), and there is a source of food, which to a fungi is almost any organic material, then mould will be produced.

Not all moulds are detrimental to health – some moulds are used in food production. However, whilst some might turn milk into a flavoursome cheese, that is not the case for all moulds and some can present a significant hazard to health.

The ubiquitous presence of mould spores means that there is a background presence of moulds that naturally occur within a property. Testing must, therefore, be able to distinguish between the background of mould and its presence due to an insurable event like an escape of water. This can be achieved by collecting background samples, which may be found just outside the property or in a non-affected area and comparing levels with an area that is known to be affected. This is also of use in dispute resolution, which can occur when there is a concern that a clean-up operation has not been conducted correctly. The presence and source of any mould growth can be identified, and further cleaning conducted, if necessary. Once identified, we consider the results, alongside detailed inspections of properties for signs of moisture, damp, humidity (i.e. the things that could/would cause mould) and establish whether these are incident-related or the result of longer-term building or ventilation issues.

Asbestos

Asbestos contamination is another issue that Hawkins frequently deals with. Asbestos is usually present in one of three forms; chrysotile, amosite and crocidolite (white, brown and blue asbestos), of which chrysotile is by far the most common. Chrysotile is the component present in, for example, artex ceilings or the corrugated cement boards used on roofs. The material was used because in addition to being low cost, it has several useful properties, such as heat resistance, mechanical strength and chemically inertness. Examples of cases involving asbestos contamination include roof damage caused by contractor activities, impact or storm damage. Assessing the presence and extent of any contamination inside the building and on stored stock or machinery, can be determined using sampling and microscopic analysis.

Summary

Contamination can affect buildings, equipment or stock. Once a contamination event has occurred, the three remedial options are repair of the damage, replacement if the item is damaged beyond economical repair, or cleaning (again if it is economical to do so). Business interruption should be factored into the calculation too, as whilst it may it be possible to clean one hundred office chairs, it could take six months, in which case it might be cheaper to replace them.

The key in all contamination cases is to quickly identify what needs to be done to fix the problem, and then take the appropriate actions to properly reinstate and minimise costs. When notified of an incident, Hawkins will normally attend the scene within one day and can identify what works need to be undertaken immediately to mitigate further loss, and can plan the longer term works to full reinstatement, as well as being fully independent from the contractors who are conducting the works.

About the Author

After graduating from University, Ed worked as an analytical research scientist at Pfizer. He specialised in analytical method development and trace analysis, with a particular focus on gas and liquid chromatography, both coupled with mass spectrometry detection. Some of this work was published in scientific literature and presented at conferences.

Ed has conducted more than 850 forensic investigations including fires, explosions, electrical incidents, contamination assessment, chemical reactions and escapes of water in domestic, industrial and marine environments. He regularly travels overseas to conduct investigations. Several of his high-profile cases have involved material losses of more than £10m, with some exceeding £100m. The marine vessel incidents have involved both engine room and cargo fires, including the TAC Imola, fires onboard large yachts and superyachts, and the MSC Flaminia, for which he gave evidence at Deposition and in the Southern District Court of New York.