Materials Failures

Our expert materials scientists and engineers have years of experience identifying the cause(s) of complex failures across a broad range of material types.

We can identify why a material failed, how an incident occurred and determine root cause such as human error, a design or manufacturing flaw, poor material specifications or process implementation.

Our Materials Failures expertise

Composites

A composite material is any multicomponent material that contains two or more distinct constituents or phases, i.e. it is made from a combination of two or more different types of constituent material. Perhaps the most familiar

Concrete & Aggregates

Concretes, screeds and aggregates are the backbone of the building industry. Without these materials many structures simply could not be built. Yet the failure of these can have catastrophic

Electronic Materials

Electronic components rely on various materials such as polymers, metals, and ceramics in order to function. Issues with any of these materials can cause failures, resulting in hazards like fires or power surges. Hawkins Forensic

Fibres & Textiles

Fibres and textiles can be used in a surprising array of critical equipment, from ropes and straps, to Kevlar gloves and PPE. Failure of these items can lead to serious injury or loss of

Glass & Ceramics

Hawkins can determine the cause of failure of ceramic and glass products which can often lead to personal injury, structural damage, loss of earnings.

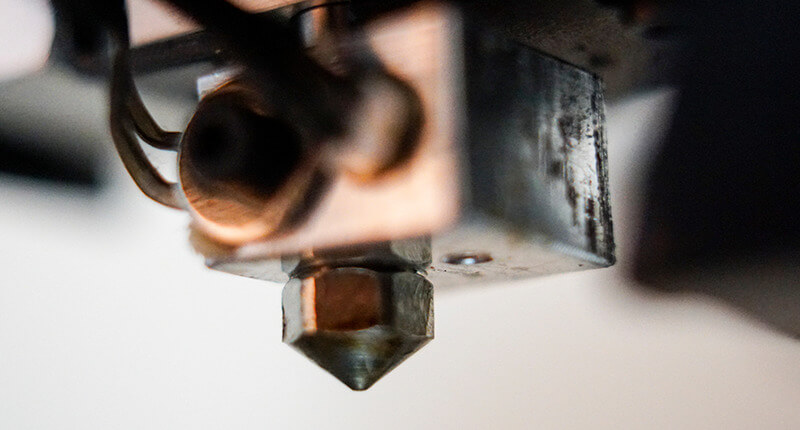

Metallurgy

Losses involving metallurgical failures occur in a wide range of industrial and domestic environments and can lead to high value claims or even loss of

Packaging

Losses involving failures of packaging can cause damaged products. This can be very costly and can lead to high value claims or even damage to reputation and loss of consumer confidence.

Paint & Coatings

Coatings primarily shield materials from preventing corrosion in metals and rot in natural elements. However, they can fail due to poor installation, curing environments, or manufacturing issues. Detailed analyses unravel the

Pipe & Plumbing Fittings

Plumbing fittings and pipes are designed to carry various liquids and gasses. They provide a crucial conduit through which many of our daily activities are achieved, in both domestic and industrial settings. If a pipework fails

Plastics/Polymers

Polymers, or plastics as they are more commonly known, are used in all aspects of modern-day life: from pipework to paint coatings, textile fibres to automotive components and adhesives to hot water bottles. Plastics are imbedded

Water Chemistry

Water chemistry is crucial when considering the compatibility of components with it. This could be ocean going structures or simply components in domestic plumbing systems. We can take samples of water and analyse them, including

Wood Degradation

Timber can be used for decorative or structural purposes; the way a piece of wood might react to environmental conditions varies hugely depending on type and cut. Hawkins has examined many claims relating to the degradation of

Download our latest Brochure

Why Hawkins?

Hawkins is an industry leader with proven expertise and practical experience, married with a real awareness of our clients’ needs.

Rapid Response

- 24/7 availability

- Early site visit

- Prompt reporting

Quality Service

- A specialist team of forensic engineers and scientists

- Proven expertise and practical experience together with a rigorous peer review system

Breadth & Depth

- Over 150 impartial experts across an international network of offices

- Over 70 different areas of specialism

Commercial Awareness

- A range of services to suit your needs

- Combining successful outcomes with cost sensitivity

“Clients come back to Hawkins because of our honesty and integrity. Our subject matter experts have sound technical knowledge and expertise, married with a real commercial awareness of what our clients need. Hawkins provides a rapid response, giving quick accurate advice and communication of the evidence in a way our clients can act upon.”

Dr Andrew Prickett, Managing Director, Hawkins