Hawkins investigates numerous escapes of water involving push-fit fittings, where it is important to determine whether the parts were defective or whether there were workmanship issues.

Push-fit fittings, sometimes referred to as push-to-connect fittings or quick-connect fittings, mark a significant improvement in the world of connection technologies for pipes and tubing. Their ease of use has quickly seen them rise in prominence, becoming a cornerstone in fields as diverse as modern plumbing, advanced manufacturing, and an array of DIY projects. It is no wonder then that plastic push-fit fittings have become a common feature in many domestic water installations. They allow plumbers to form a joint by simply pushing a pipe fully into the fitting; a retention feature within the fitting then ensures the pipe remains firmly attached.

Compared with other types of plumbing joints, push-fit fittings bring several benefits:

- The joints are easy to form without the use of specialised tooling.

- The joints are effective instantly; no need to wait for soldering material to cool down or for a chemical bond to form.

- The ease with which the joints can be taken apart and reused (ease of disassembly and reuse is a particularly attractive feature when buildings have to be altered or when the work is done in stages).

As a result of their versatility, push-fit fittings have proved popular with both tradespeople and DIY enthusiasts alike but, conversely, are becoming an increasing concern to the UK insurance industry. An online article published in April 2023 by Copper Sustainability Partnership¹ states “new research cites plastic push fittings as [a] leading cause of water leaks. […] In the past eight years alone, the total cost of escape of water claims has nearly doubled, with these claims currently costing UK insurers £2.5 million a day.”

How Does a Push-Fit Fitting Work?

Push-fit fittings are well suited for use with plastic pipes, but they can also be used with copper pipes. It is not uncommon for a plumber to use a push-fit fitting to connect a copper pipe on an existing system to a new plastic one. The fittings can be made from plastic, which is not prone to corrosion. Experience has shown they are suitable for use with either slightly acidic or alkaline water, and fittings able to sustain temperatures above 100°C for a short duration of time (a few hours) are commonly available. They can therefore be used on mains cold water, domestic hot water and central heating systems.

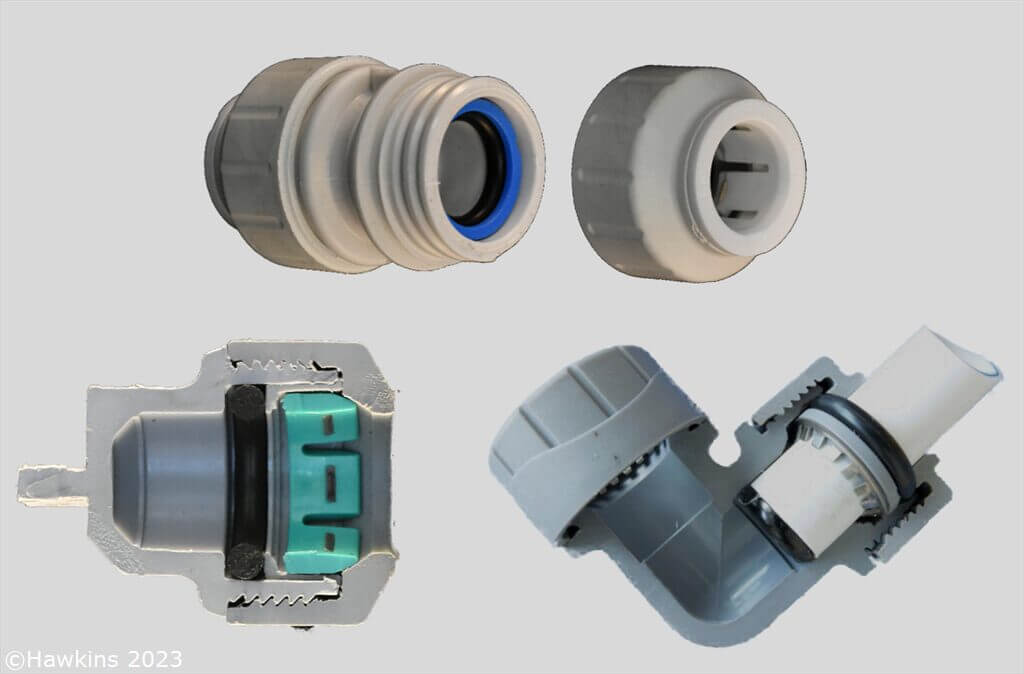

Manufacturers are marketing a broad range of push-fit fittings with slightly different shapes and functions, but the fundamental concept is based on three main elements:

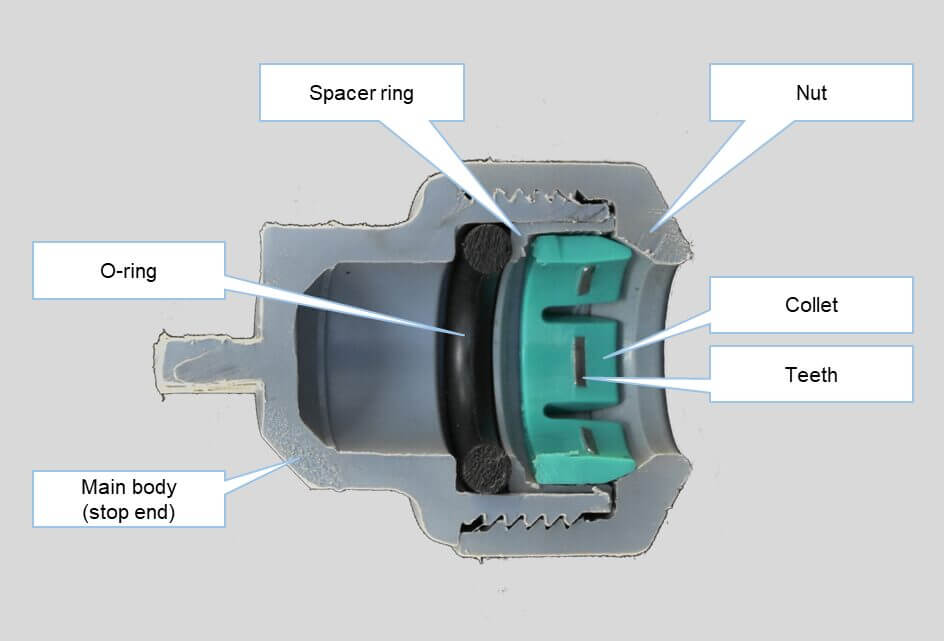

- An O-ring to provide a waterproof seal

- A retaining device to prevent the pipe from being pulled out of the fitting unintentionally (the retaining device is often a collet fitted with inward-pointing teeth).

- A mechanism, typically a nut, that keeps the retaining device in position but also allows the disassembly of the joint (following disassembly, both the pipe and the fitting could be re-used provided they are not damaged).

When a pipe is inserted fully into the fitting, the O-ring is pressed between the pipe’s outer diameter and the inside of the main body’s socket to create a watertight seal. The collet teeth are designed to allow the pipe to pass into the socket, but bite into the outside of the pipe and resist its extraction from the socket.

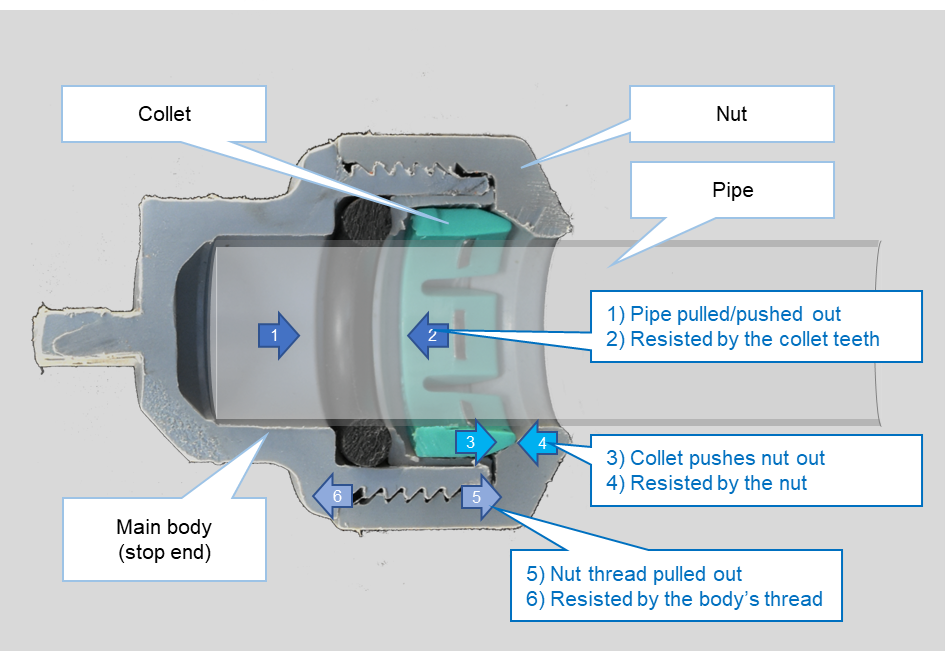

The harder the pipe is being forced out, either from internal water pressure or a pulling action on the pipe, the stronger the reaction of the nut onto the collet and the stronger the bite of the teeth into the pipe. A push-fit fitting’s ability to withstand water pressure or pull-out forces is reliant on the nut keeping the collet teeth tightly pressed onto the pipe.

The Downside of Popularity

Due to their popularity, manufacturers produce millions of push-fit fittings every year. Despite rigorous quality controls being in place, given the large volume of products manufactured, the possibility of a defective part being supplied into the marketplace cannot be discounted.

The fittings are installed across a wide range of properties with very different characteristics in terms of water pressure, temperature, and type of installation. The fittings, therefore, encounter a broad range of conditions in service. In some instances, these conditions could prove quite severe. For example, properties with higher water pressure or following maintenance work which has caused sudden water pressure variations can influence the reliability of the fittings. Although the “Water Regulations Guide” states that fittings should not be embedded in a wall or solid floor, Hawkins has come across push-fit fittings installed where they are hidden from view, either underground, under floors, or within walls. When fittings are concealed, escapes of water may take longer to become detectable and, consequently, cause more severe damage.

Installation or manufacturing quality issues can have a detrimental effect on the reliability of a push-fit fitting in service. For example, when a fitting is re-assembled on-site, and the nut is not fully tightened during the re-assembly process. Alternatively, under the influence of repeated pressure fluctuations (e.g. caused by the opening and closing of taps) or of a load sustained over a prolonged period, the force-resisting capacity of the threads between the nut and the fitting could be exceeded. This results in the nut being pushed out of its intended position. The nut can then be displaced relative to the main body or detached from the main body, to the point that the watertight seal between the pipe and the socket is broken and water is able to escape.

Narrowing Down the Possible Causes

The reliability of a fitting is a function of multiple processes, including product design, material selection, manufacture, assembly, installation, and testing on-site. Identifying the main process step responsible for a reliability/quality issue is key to enabling rapid and cost-effective remedial actions. Problem solving methods, such as Six Sigma, provide a proven framework to identify the causes of quality related problems. Six Sigma uses a range of statistical tools to narrow down the possible causes and reduce subjective bias in the interpretation of data.

One of these tools is the “normal distribution”. The normal distribution assumes that random and independent measurements of a given characteristic, such as mechanical strength, would be spread equally around an average value.

This assumption is generally suitable for manufactured products due to the averaging effect of the many processes involved in their design and production. The spread of values would typically account for variations caused by product design, material properties, manufacturing capability, and measurement repeatability.

Using data recorded on example fittings (exemplars) for a specific characteristic, a normal distribution can be used to predict where a defined percentage of fittings, usually 95% or 99.7%², would be expected to be for that characteristic. These predictions can then be used to determine whether fittings that have failed in service (exhibits) differ from the ‘norm’.

Case Study

During an escape of water investigation, Hawkins’ site inspection revealed that the nut of a push-fit fitting had been displaced and had allowed water to escape. The investigation confirmed that the failure was not the result of an installation issue but suggested instead that the mechanical strength of the fitting’s nut might be less than expected. In this instance, the shape of the nut made it impractical to measure its mechanical strength directly. However, since the nut was made of ‘nylon’, a plastic material, the nut’s mechanical strength was known to be proportional to the nylon’s ‘molecular weight’ (i.e. the length of the nylon molecules in the nut). The longer the molecules, the more viscous and the stronger the material. Determining the molecular weight of the fitting was a more practical option to evaluate, by proxy, the mechanical strength of the nut.

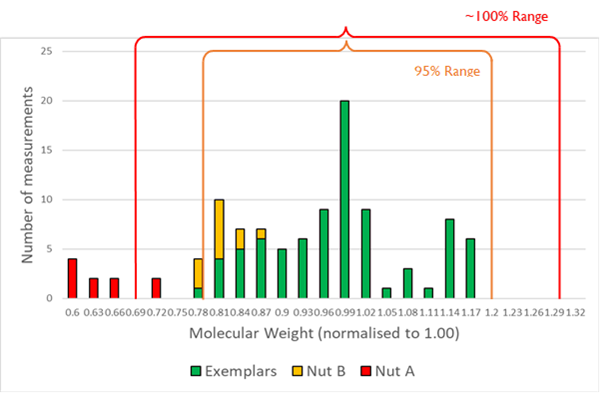

The molecular weight of exhibit and exemplar nuts was assessed. Multiple measurements were recorded on each nut to reduce the contribution of measurement errors. The fitting involved in this connection was a straight coupler with two end nuts. The molecular weight of each end nut was assessed on all specimens. The exemplars’ measurement data were grouped but the exhibits’ data for the two end nuts, labelled Nut A and Nut B, were analysed separately. The data were therefore split into three groups; values for (1) the exemplars, (2) Nut A, and (3) Nut B. The normal distribution was used to predict the ranges where 95% and 99.7% (~100%) of the molecular weight values were expected to lie for this type of fitting.

The data were normalised such that the molecular weight (thus the strength) of an average fitting had the numerical value of ‘1.00’. The data showed that Nut B’s values were less than ‘1.00’ and, although they were at the low end of the 95% range, they were still comparable to typical values of molecular weight for exemplars. Therefore, Nut B’s strength was expected to be broadly representative of this type of fitting. Nut B did not fail in service. Consequently, there was no reason at this stage to question the suitability of the fitting’s design or material selected.

Nut A’s values were mostly outside of the ~100% range, i.e. they were unusually low for this type of fitting. From the analysis, we could infer that Nut A’s mechanical strength was below that of the exemplars. Nut A failed in service and caused the escape of water. Because Nut A’s values were mostly outside of the predicted ~100% range, Nut A’s strength was not representative of that type of fitting. The statistics indicated that an unusual event or ‘special cause’, had occurred and caused the reduction of Nut A’s mechanical strength. This observation pointed towards the possibility of a quality or assembly issue rather than a generic design or manufacturing issue.

The next step in the study would be to evaluate with the manufacturer the possible reasons for the reduced strength, such as an undetected quality issue with a batch of material or an incorrect part being used in the assembly. Remedial actions could then be identified to prevent re-occurrence of this issue.

About The Author

Gerald spent 20 years in the aerospace industry where he gained extensive experience in the design and manufacture of complex products. Throughout his career, he has had a keen interest in continuously improving new products and has been involved in root cause analyses and solving materials, mechanical, or systems engineering problems.

He is a Chartered Engineer with the Institution of Mechanical Engineers and is a certified Six Sigma practitioner. Six Sigma is a general problem-solving framework that can be applied across a range of products and issues. It is particularly well suited to identify root causes and address quality concerns with manufactured products.

If you would like to instruct a Hawkins engineer to determine the cause of a product failure, please get in touch.