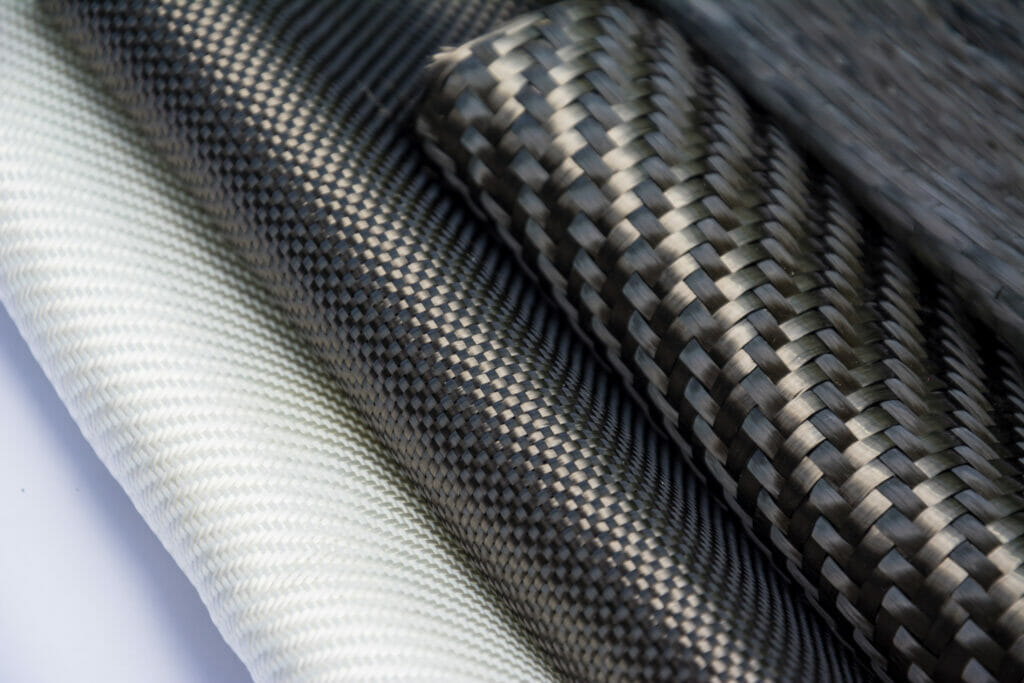

Failure Investigation of FRP Composite Parts

In this article, Amir will discuss what a Fibre Reinforced Polymer is, how they are made and how their failures can lead to catastrophic loss.

Hawkins Enhances Investigative Capabilities with XRF Training

Hawkins Materials experts received training on how to use an X-Ray Fluorescence machine. This helps our experts to identify unknown substances, contaminants and metal compositions quickly and accurately.

Chemical Analytical Techniques in Forensic Investigations

Forensic investigators occasionally need to turn to analytical chemistry to solve a case and effect a recovery or repudiate a claim. James discusses the techniques Hawkins use and their application in real cases.

International Women in Engineering Day

We celebrate our Female Engineers on International Women in Engineering Day 2025

Hawkins Welcomes Synthetic Chemistry Expert, Dr Mehul Jesani

We are delighted to welcome Chemistry and Contamination expert Dr Mehul Jesani to our London office.

Chemical Analytical Techniques in Contamination Investigations

In this webinar, Dr James Morris explores the critical role of chemical analysis in forensic science. He introduces key analytical techniques such as chromatography, mass spectrometry, and spectroscopy, and explains how they are used to identify and quantify substances in complex investigations.

Contamination of Plastic is Not so Fantastic

Forensic Materials Engineer Jacek Czech provides insight into how polymeric materials can become contaminated and how this can lead to failures.

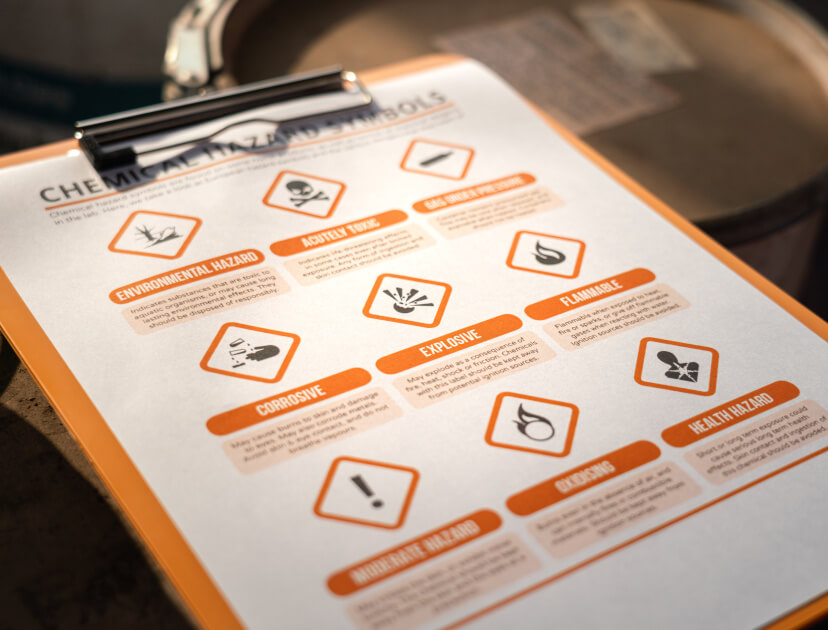

Chemical Hazards

In this presentation, Dr Ben Barron discusses some of the inherent chemical hazards found in chemistry laboratories and processing areas, applicable to both academic and industrial settings.

Breaking the Mould

In this presentation James investigates some of the many types of mould species, how they can be used to determine the cause and the timing of contamination, and their potential effects on air quality and human health.

A Scientific Approach to the Problem of Post-Incident Recovery

Forensic Chemistry Expert Ed Hammersley will talk about different types of contamination, their sources, and how they are detected and quantified.