Hawkins Deliver Presentations to RSA Insurance Group

Last month, members of our Fire , Power, and Engineering teams gave a technical presentation to RSA Insurance Group at DAC Beachcroft’s Manchester Office.

Hawkins Hosts Renewable Power Event in London

Hawkins’ Power & Energy team hosted their inaugural Renewable Power Event in London. Presentations covered subsea power cables, wind turbine failures, solar farm issues, and structural failures in renewable energy. The event provided a platform for networking and showcasing Hawkins’ expertise in the renewable energy sector.

Jack Holderness

Jack is an electrical engineer who started his career in 2010 by completing a JIB approved apprenticeship in Electrotechnical Technology and Installation.

Hawkins Sponsors and Presents at PCPUG 2024

For the second year in a row Hawkins sponsored and presented at the annual 26th Technical Forum – Philippine Coal Plant User’s Group.

Hugh Martindale

Hugh is a Chartered Engineer with the Institution of Mechanical Engineers. He has degrees in Architecture and Mechanical Engineering with Business Finance, and a Mechanical Engineering PhD from University College London (UCL) on the behaviour of flexible pipe tensile armour in the region of an end fitting.

Albert Richardson

Albert is an Electrical and Rotating Machines Engineer with over three decades of experience in the field. He is recognized for his expertise in generators and high-voltage (HV) motors, primarily focusing on power generation and distribution.

Systemic Failure in the UK Solar Fleet

Ben will look at three common types of failure in electrical equipment at UK solar power installations, and discuss whether the differences between ‘old’ and ‘new’ power systems and practices might have a contributory role.

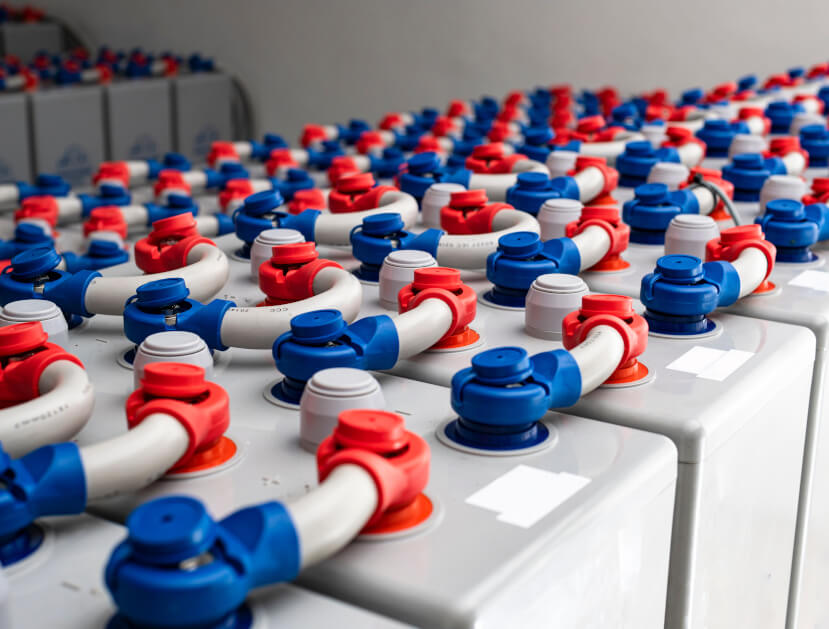

Testing Times – Challenges Associated with Testing Power Plant Systems

Nick will discuss the challenges associated with testing and maintaining the integrity of power plant protective and back-up systems.

Power Investigation Challenges: Techniques & Evidence That We Collect

Nick showcases some techniques that we can use to investigate an incident and the evidence that we can collect to support in recovery or litigation. He will also cover some of the challenges faced when investigating.

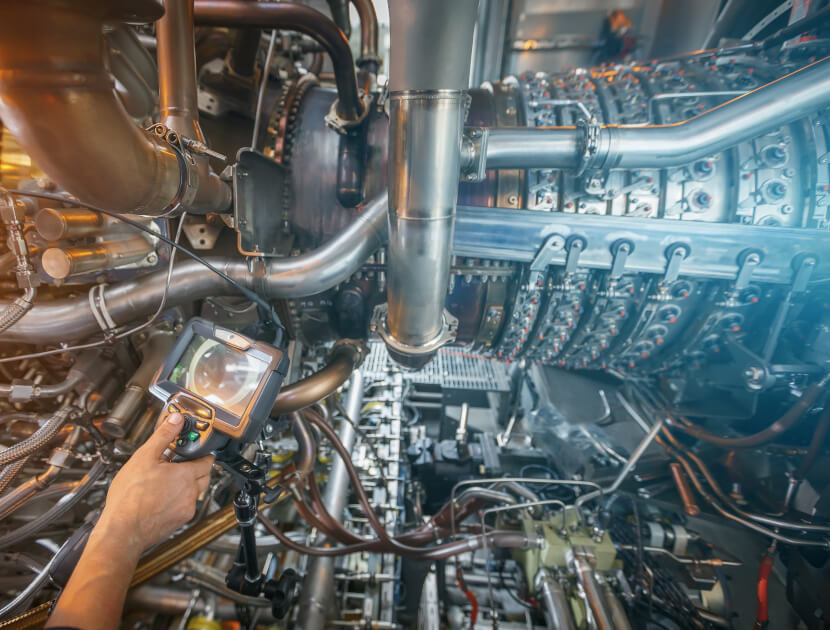

Gas Turbines & Hydrogen Through the Energy Transition

As power generation shifts to renewable energy and sustainable fuels, gas turbine engines will continue to play a crucial role in maintaining energy demand. Simon discusses the challenges and mitigations of running gas turbines through the energy transition.

Italiano

Italiano