Metallurgy

Losses involving metallurgical failures occur in a wide range of industrial and domestic environments and can lead to high value claims or even loss of life.

Incidents might involve structural collapses or mechanical failures that result from corrosion, fracture, wear or deformation (bending/buckling) of metallic parts. Such catastrophic failures sometimes result from problems in the manufacture of the parts or from the inappropriate selection of a particular material (which is itself well made) for the job in hand.

The use of metals is widespread, from structural steels in welded fabrications, to copper electrical wires, brass plumbing fittings, or extruded aluminium ladders. Metallurgy is the understanding of metals and alloys, their performance, and the ways they fail – each type of metal behaves differently at high or low temperatures, and can corrode or crack under certain conditions.

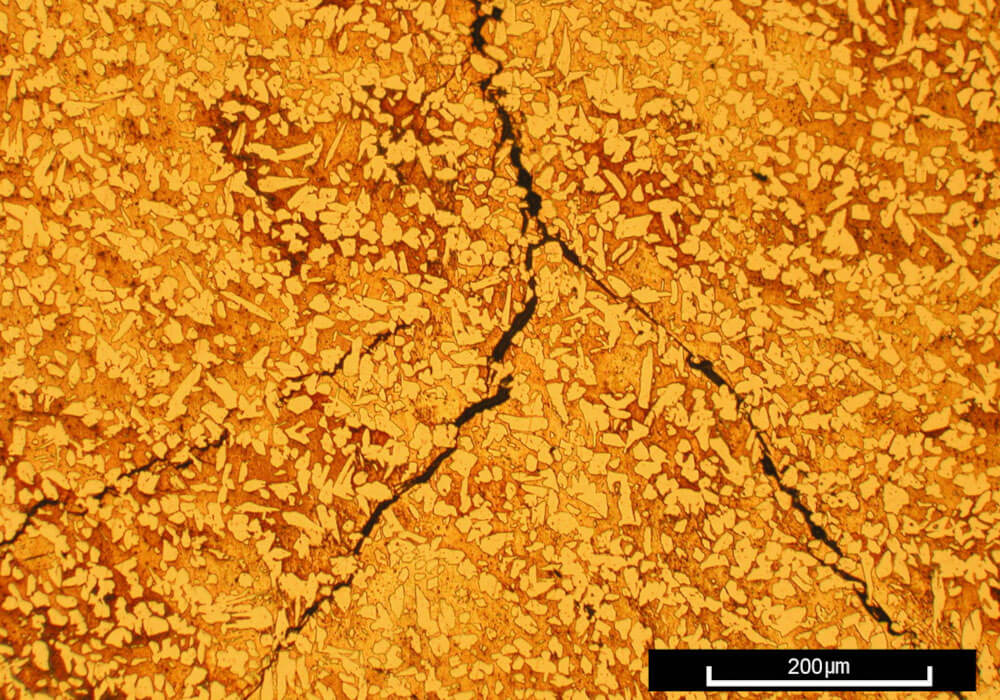

Metallurgists at Hawkins identify what has caused metal to fail and why, using a combined understanding of the chemistry and microscopic crystal structure of alloys along with the large-scale failure modes of metallic components. We can investigate such failures by carrying out detailed inspections of the components and considering the environment and the application, in order to differentiate between issues such as defective machinery, operating errors, poor maintenance and other external causes.

Having our own laboratories and equipment means that we can complete specialised testing of metallic components to establish the true nature of the failure (for instance whether a fracture was instantaneous or gradual), which might have implications for policy coverage.

We use well established metallurgical techniques to discover whether a component was specified or made as it should have been, in order to provide options for recovery and to understand ongoing risk considerations.

WHY APPOINT A FORENSIC INVESTIGATOR?

We have the technical knowledge and experience to tell you why a metallurgical failure or catastrophic incident occurred, not just what caused it.

While it may seem evident that a metal has cracked, corroded or broken, appointing a forensic metallurgist will help identify whether the alloy composition was suitable for the application, whether the environmental conditions contributed to the cracking, or if damage occurred when a component was installed or welded for example.

- We provide you with the answers you need to determine why an incident occurred and so assist in repudiation/cover decisions and fraud identification.

- Our experts have a wide range of industrial experience, including detailed knowledge of metal grades, manufacturing processes and applications and can carry out targeted research to support investigations.

- We have laboratories equipped with high-specification microscopes for examination of metal samples as well as access to specialised equipment in external laboratories.

Where samples cannot be removed for laboratory analysis (such as steel in buildings/structures), our metallurgists can do on-site metallographic preparation of replicas so that the microstructure can be examined under laboratory microscopes. Site hardness testing can also support these investigations.

- We will help you to determine if an incident could have been avoided.

- We provide consultancy advice to prevent similar events happening again in the future.

- If removing a risk entirely is unavoidable, we advise on steps to take to mitigate the risk and reduce the potential damage resulting from an incident.

- We advise on servicing, maintenance and repair regimes.

Our experts in metallurgy and welding engineering can provide support for cases ranging from industrial arbitrations to personal injury cases.

- We support subrogation/recovery efforts.

- We help you to make decisions regarding where legal responsibilities/liabilities lie.

- We help you to defend wrongful claims.

- We produce reports suitable for Court and litigation.

Examples of Typical cases

- Arcing or contact alloying in a fire investigation.

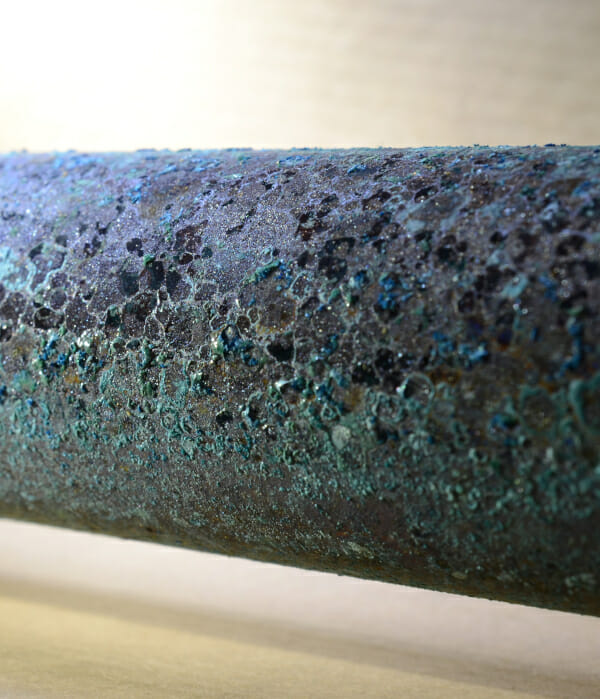

- Pitting corrosion of leaking copper pipes.

- Stress corrosion cracking in fractured brass plumbing fittings.

- Chemical analysis of brass to identify de-zincification.

- Corrosion of stainless-steel reinforced hoses for conveying water or oil.

- Loss of rigging from an ocean-going sailing yacht.

- Assessing flaws in steel welds.

- Corrosion assessment in rolled steel products.

- Pre-existing damage on items causing personal injury.

- Collapse of a large sculpture.

- Failure of large industrial storage vessels, power generation hardware and agricultural machinery.

- Fractography to determine failure mechanism(s).

Our services are flexible and can be tailored to your needs, depending on the scale and urgency of the investigation. Our services range from a free consultation through to a full investigation including a court-compliant report for the support of legal action.

If you would like to discuss how we can assist you please fill out our enquiry form or call us for a free consultation.

HOW DOES HAWKINS INVESTIGATE METALLURGICAL FAILURES?

1

Consultation

We like to speak to you before we conduct any work, to establish the scope of the investigation and the value we can add to a case. These discussions help us to understand your requirements, as well as identify any background information which is available in terms of material certificates, fabrication records or installation instructions, design drawings, and maintenance records. We are also happy to provide you with an estimate of the cost of conducting a forensic investigation.

2

Inspection

If required and with your agreement, we will arrange to visit the scene to inspect the damage and examine the circumstances around the material failure. Wherever possible, we will retain faulty parts for examination in our laboratory, where we use a range of equipment, tools, and tests to determine the cause of the failure. This could include microscope examinations, recreating an installation in a controlled environment, or testing exemplar components or materials.

3

Conclusion

Once our examination is complete, we will discuss our findings with you and prepare a report containing a detailed account of our investigation, conclusions, and where appropriate, further work or advice.

Case Study

Brassed off…

Water leaking from a plumbing compression fitting caused significant property damage.

The brass olive in the compression fitting had areas that looked copper-coloured rather than golden brass-coloured. Cutting a section for metallography showed cracking through the olive that would have provided the leak path. Chemical element mapping of the section in an electron microscope confirmed de-zincification of the brass, and supported the conclusion that the olive was not suitable for use.

SPEAK TO ONE OF OUR EXPERTS

Principal Associate

- Composites ,

- Glass & Ceramics ,

- Metallurgy ,

- Plastics/Polymers ,

- Escapes of Water, Oil & Gas ,

- Construction Injuries ,

- Falls from Height ,

- Marine Coating Failures ,

- Materials Failures Onboard Ships ,

- Materials, Chemistry & Biology ,

- Concrete & Aggregates ,

- Electronic Materials ,

- Fibres & Textiles ,

- Packaging ,

- Water ,

- Wood

Related areas of expertise

Composites

A composite material is any multicomponent material that contains two or more distinct constituents or phases, i.e. it is made from a combination of two or more different types of constituent material. Perhaps the most familiar examples in modern engineering are glass or carbon fibre reinforced plastic (GFRP or CFRP).

Plastics/Polymers

Polymers, or plastics as they are more commonly known, are used in all aspects of modern-day life: from pipework to paint coatings, textile fibres to automotive components and adhesives to hot water bottles. Plastics are imbedded into our way of life, and failure of these materials can lead to personal injury, escapes of water, loss of earnings, to name just a few outcomes.

Glass & Ceramics

Hawkins can determine the cause of failure of ceramic and glass products which can often lead to personal injury, structural damage, loss of earnings.