A fire’s area of origin can be difficult to determine when it has been burning for a considerable time or if it has involved a large area. Patterns of fire damage used by investigators following very severe fires might point to the seat of the fire, but equally, they might indicate areas where the fire has vented the building causing severe damage or where a greater load of fuel was available. Our research involving compartment fires explored the reliability of a technique called “arc mapping” which uses the electrical wiring in a building to establish the origin of a fire. The analysis of three-dimensional data collected during the research indicated a high probability that localised melting on electrical conductors known as ‘arcing damage’ occurred in close proximity to the fire’s area of origin.

WHAT IS ELECTRICAL ARCING?

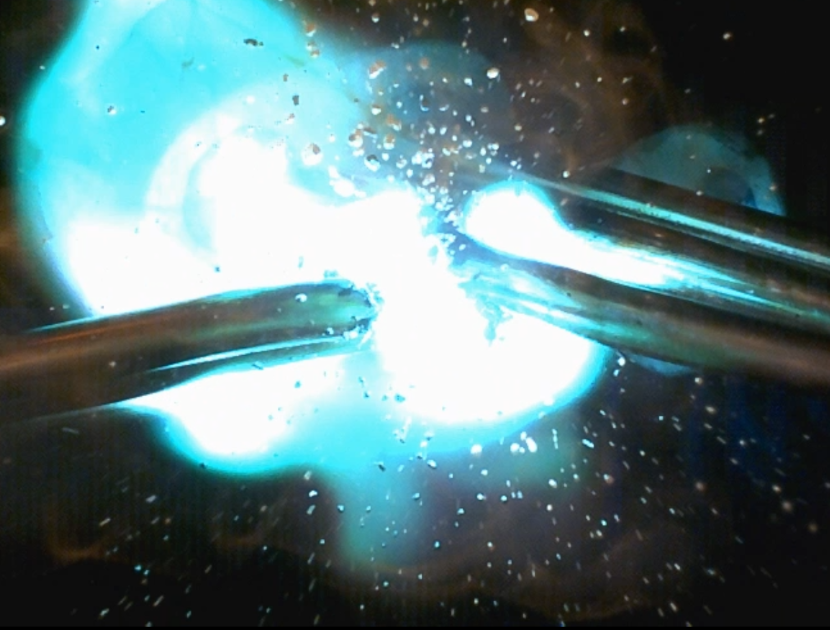

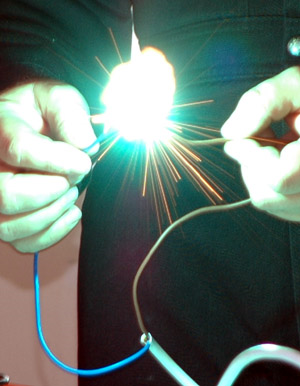

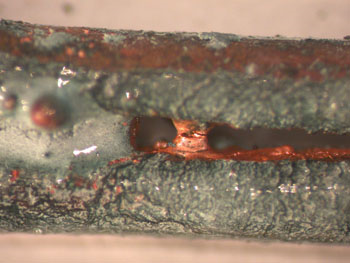

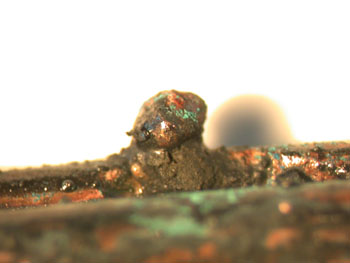

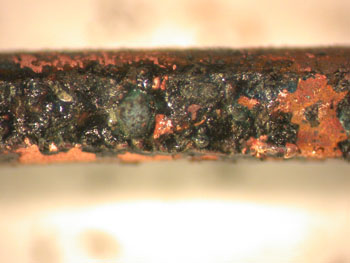

Arcing is defined as “a high temperature luminous electric discharge across a gap or through a medium such as charred insulation”. Below is a demonstration of arcing by the author when two wires (conductors) were shorted together at mains voltage. The copper conductor melts and forms a bead(s) and/or notch(es) on the wire’s surface.

The beads and notches known as “arcing damage” can be useful to a fire investigator because they provide reliable information to assist in establishing a fire’s area of origin. Arcing damage usually shows the point where a fire first attacked a live electrical circuit. This can be of particular importance when the fire has reached full involvement or flashover. When flashover occurs in a room the patterns of fire damage, often relied upon by fire investigators, are overprinted and confused, rendering them less reliable. Arcing damage is sometimes the only way of establishing where a fire started.

WHAT IS ARC MAPPING?

One area of potential confusion in using arcing damage is that during very severe fires, the high temperatures reached can melt copper conductor(s). This effect can create evidence which appears to the inexperienced eye, to be similar to arcing or it can mask arcing created earlier in the development of the fire.

Generally, arcing will cause the circuit protection device (fuse or circuit breaker) to operate so that no further arcing can occur on that circuit. By finding the location of arcing damage on several cables, the fire’s area of origin can be progressively reduced in size. If arcing damage is found inside the casing of an electrical appliance, it is usually a good indicator that the fire started within that appliance.

Prior to this research, the reliability of arc mapping had not been confirmed, so a series of full-scale experimental fires were conducted at our GATR fire test facility in Essex, where different compartment scenarios were repeated. 42 fully-furnished compartments were wired with four electrical circuits, which led to the generation of 141 examples of arcing on copper conductors. Figures 1 to 10 detail nine separate categories of arcing damage, following the experiments.

These tests established clearly the relationship between the fires area of origin and the location of arcing damage. The results identified the reliability of using arc mapping at fire scenes to establish where a fire started.

CONCLUSIONS

Analysis of the three-dimensional data recorded during 42 experiments showed that there is a high probability of arcing damage affecting electrical conductors located close to the origin of a fire. The research highlighted the value of finding arcing damage during a scene investigation particularly when the fire has developed to flashover or involves a large area.

ABOUT THE AUTHOR

An ex-firefighter, Nick has undertaken a number of electrical examinations within the UK. This has included multi-agency teams investigating several firefighter fatality incidents and the investigation into the cause of the Cutty Sark fire in Greenwich. He has delivered electrical training to Fire Brigades, Police Forces and Forensic Laboratories and presented at training conferences both within the UK and overseas. Nick’s experience in fire investigation led to him being asked to chair the writing group for the now published judicial primer “Fire Investigation – A Primer for Courts.”