Failures in the built environment are often caused by issues related to the ground. Typically due to a lack of understanding of the geotechnical risks. One of the most significant geotechnical threats to the UK’s built environment is the presence of abandoned mines hidden below the surface. An assessment of this risk by a geotechnical engineer is essential for new developments in areas affected by historical mining yet is often inadequate or simply overlooked. The consequences can range from minor subsidence to catastrophic collapses.

The Problem

Mining of the UK’s wide variety of mineral deposits has been going on for centuries. It is estimated that around 15% of Great Britain is within areas affected by past or present mining. These mines can be broadly classified into either:

- Surface mines, where minerals are extracted in bulk from surface excavation, or

- Underground mines, where mineral deposits are extracted from below ground, using shafts, tunnels and adits

Underground mines can be shallow or deep and are probably most commonly associated with the extraction of coal. A clear challenge with underground mines is the lack of physical evidence at ground surface.

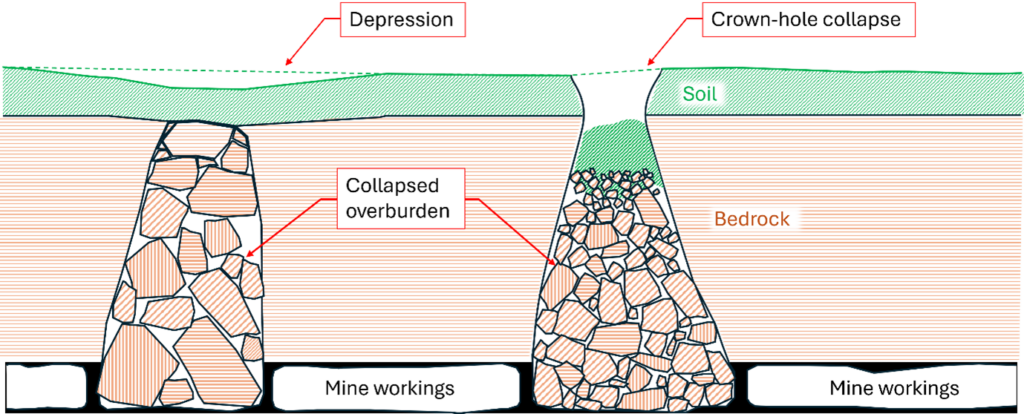

Only recently has serious consideration been given to the long term environmental impact of abandoned mines. Workings from historical underground mining activities were typically left open, unsupported and potentially unstable, with little regard to the risk of future collapse. Ultimately, for developers or landowners, the collapse of underground mine workings is a concern as it can result in the expression of subsidence at ground surface. This may manifest as a depression in the ground, or localised ‘crown-holes’ (sinkholes associated with mining activity). In any case, the impact on the built environment can be costly, both financially and in terms of safety.

Collapse of historical underground mines can be triggered by human activity, such as increased imposed loading from new buildings, structures or earthworks, or disturbance from construction activities like piling, excavations or compaction. Collapse can also be progressive, occurring slowly over time due to natural deterioration of the mine or weathering. A collapse may not require any external triggers and could occur completely independently. This means that even developments completed many years ago may still be at risk if adequate assessment and mitigation was not undertaken prior to construction.

Abandoned mining hazards are not just limited to below ground workings. Other mining features such as shafts or adits (vertical or horizontal tunnels that would have originally provided access to the below ground workings) also pose risks. These features present particular risks as they are often unprotected and very close to the ground surface. Additionally, abandoned mine workings may contain harmful gases or water. Development activities can create pathways for these substances to escape, with potentially catastrophic consequences.

To add further complexity to the matter, legislation requiring mine-owners to deposit plans and keep records of their activities was not passed until the late 19th century, towards the end of the industrial revolution, meaning earlier mining activity is largely undocumented. Furthermore, post-legislation records, are often inaccurate or incomplete.

The result? A mining legacy problem that presents significant risks to the built environment.

Ultimately, responsibility and subsequent liability rests with the landowner and/or developer. An owner, purchaser or prospective developer of land within an area known to have been affected by past mining may be required to appoint a geotechnical engineer to assess the risk. For example, commercial developers on most notifiable projects have a statutory requirement, under the Construction (Design and Management) Regulations 2015, to appoint a Principal Designer with sufficient knowledge, experience and ability to identify, eliminate and control foreseeable risks in the pre-construction phase. Typically, for mining risks, this should be done using the steps set out below.

The Solution

Preliminary Study

The requirement for a general preliminary study to collect relevant geotechnical information for a site is set out in BS EN 1997-1:2004 (Eurocode 7 – Geotechnical Design). This should include information related to historical mining at the site. This step is largely desk-based, making it relatively low-cost and efficient and will inform as to whether further investigation is needed. Broadly speaking, with respect to historical mining, this study should predominantly involve a review of publicly available information and obtain mine plans and records from relevant sources.

The information obtained in the desktop study will inform an initial assessment of the risk posed to the site. If the risk level is deemed to be too high, further work or mitigation will be required to lower the risk to an acceptable level. This may include a ground investigation and, dependent on the findings, remedial works to stabilise any mine workings.

Ground Investigation

If required following the preliminary study, a ground investigation may be necessary to identify the nature of any mine workings located below the site. For new developments, some form of ground investigation is typically required under Eurocode 7, anyway. Reference should also be made to Andrew Reeves’ previous article, Investigations Into Ground Related Failures Part 1 – Ground Investigation Issues – Hawkins Forensic Investigation. which highlights the importance of ground investigation in managing geotechnical risk.

A mining ground investigation should encompass a number of intrusive boreholes and may also include non-intrusive geophysical techniques. The ultimate purpose of the ground investigation is to develop a 3D ground model showing the depth and location of mine workings relative to the ground surface and development site. A suitably qualified geotechnical engineer can then consider factors, including the thickness of workings and the condition of the overlying ground, to determine the likelihood of subsidence. Based on this, they can decide what (if any) further mitigation measures are required to bring the residual risk to an acceptable level.

Acceptable mitigation measures may involve alterations to the development design proposals, such as the location of structures or type of foundations, or direct remediation measures, as outlined below.

Remediation

If direct remediation measures are required, a geotechnical engineer should design an appropriate scheme based on the needs of the project. A common and robust technique is drilling and grouting, whereby the mine workings are stabilised by injecting grout into the sub-surface voids through a series of boreholes. In theory, this prevents the roof of the mine from collapsing and ultimately prevents the subsidence events like those illustrated in Figure 1.

Other less intrusive and more cost-effective remediation techniques may be sufficient depending on the level of risk. These techniques include the use of softer engineering solutions, such as geosynthetic reinforcement, which act as a ‘shield’ to protect against collapses, rather than preventing it outright.

Remediation of mine shafts and adits could involve grouting, bulk-infilling or ‘capping’ with reinforced concrete.

In all cases, there needs to be justification for the remediation measures implemented. Often, clients are not made aware of the risks at the early stage of the project, and so sufficient time and budget is not allowed for remediation. Problems can begin to arise at later stages of the project when remediation becomes necessary but is either inadequately implemented or causes significant commercial issues.

So What?

If a mining-related failure is suspected, determining the root-cause is key to determining liability. Failures can occur due to inadequate assessment and mitigation of the mining risk by the client or designer, or from design or construction defects related to the remediation scheme. In other cases, actions of a third party may be causative.

As with many aspects of geotechnical engineering, there are often no hard and fast rules for understanding the risks from abandoned mine workings. Soils and rocks are inherently complex and variable, being three-phase materials (solid particles, with water and air between), unlike man-made engineering materials such as concrete and steel, meaning there is always an element of uncertainty. Each site and development are different and often needs a geotechnical engineer to apply a combination of standards, published literature and engineering judgement to manage this uncertainty and reduce risks to acceptable levels.

At Hawkins, our geotechnical experts come from design and construction backgrounds. They have direct experience in assessing risks from historical mining and in designing and implementing ground remediation for developments. This means we have the expertise to investigate these failures and determine their root-cause. To help avoid these failures, we also offer pre-risk assessment services and review ground remediation solutions for adequacy. If you need the services of our geotechnical engineers, or any of our other experts, please get in contact.

About the Author

Jack is a Chartered Civil Engineer specialising in geotechnical engineering. Since joining Hawkins in January 2025, he has investigated multiple civil and geotechnical cases involving subsidence, sinkholes, slope failures and structural damage. Prior to this, he worked for a global engineering consultancy as a geotechnical engineer on a range of infrastructure projects throughout the UK. His work included projects in areas affected by historical mining, where he was responsible for assessing the mining risk and designing remediation solutions.

Italiano

Italiano