Power & Energy

The power and energy industry faces a unique set of risks, not only from equipment failures but also from natural disasters and cyberattacks.

Equipment failures are rarely straightforward and often result due to a combination of issues from the physical equipment, it’s operation, the level of maintenance and the policies and procedures in place to try and prevent such issues occurring. When such incidents occur, insurance claims become a vital tool for businesses to recover losses and maintain operations.

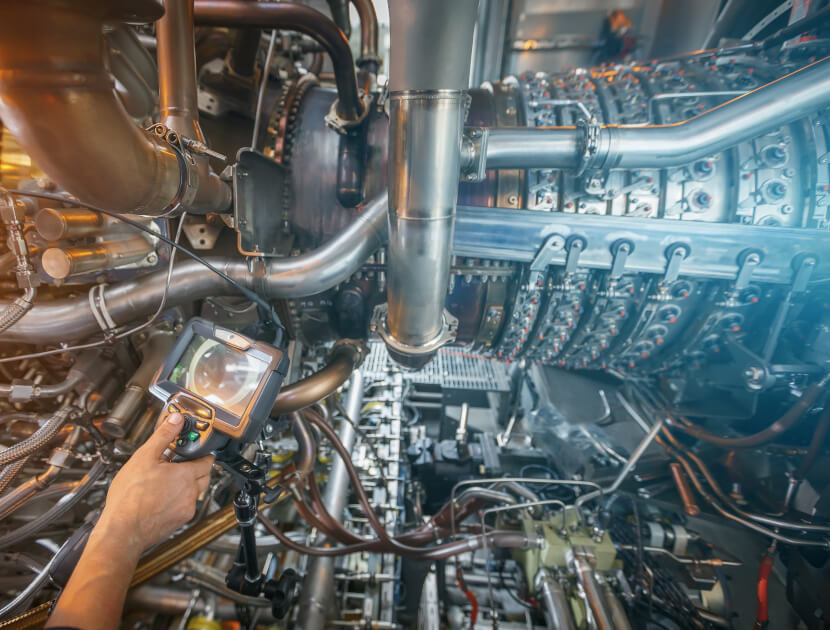

Forensic engineers play a crucial role in investigating these claims. They specialise in analysing the physical damage, witness accounts, the operational history and the policies and processes surrounding the damaged equipment to determine the root cause. By identifying the underlying causes of these incidents, forensic engineers can, where required, help insurers assess liability.

Our experts come from a range of backgrounds, from designers and manufacturers of the equipment, to technical consultants and operators of power and energy plants. As such, we are able to support beyond root cause analysis, assisting with the scope of repair works, expected costs and potential options to mitigate the business interruption.

Our Power & Energy expertise

Oil and Gas

Oil and gas operations are inherently hazardous and often involve high-pressure and high-temperature services, increasing equipment susceptibility to material degradation and mechanical failures.

Renewables

Hawkins, have engineers and scientists who come from design, consultancy and operational backgrounds across the full range of conventional thermal power technologies, who can understand the full depth and breadth of the issues

Thermal Power

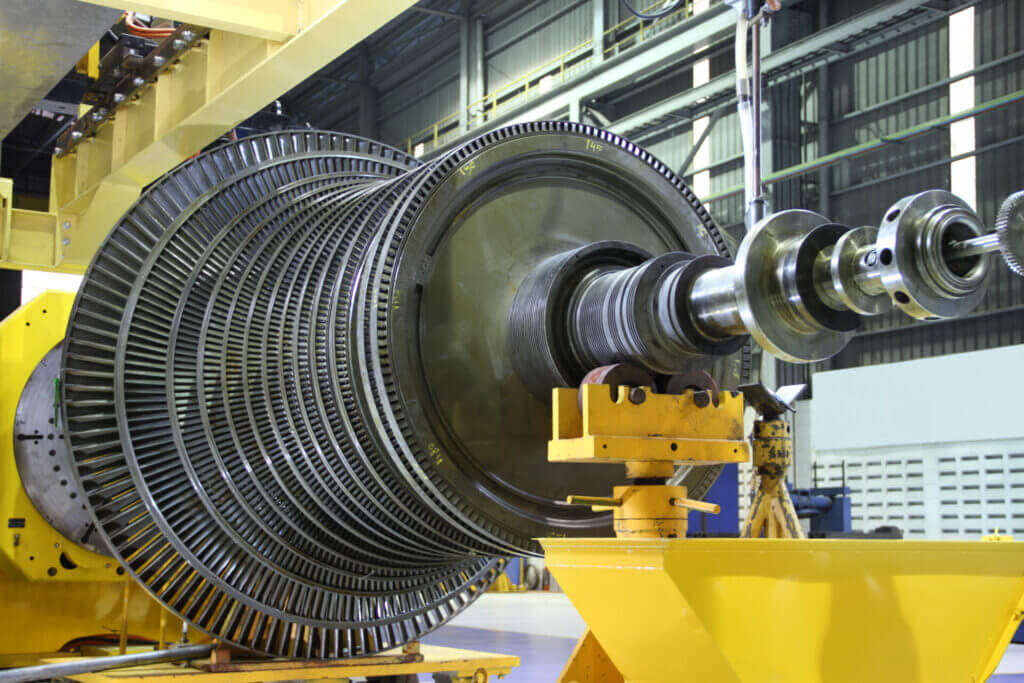

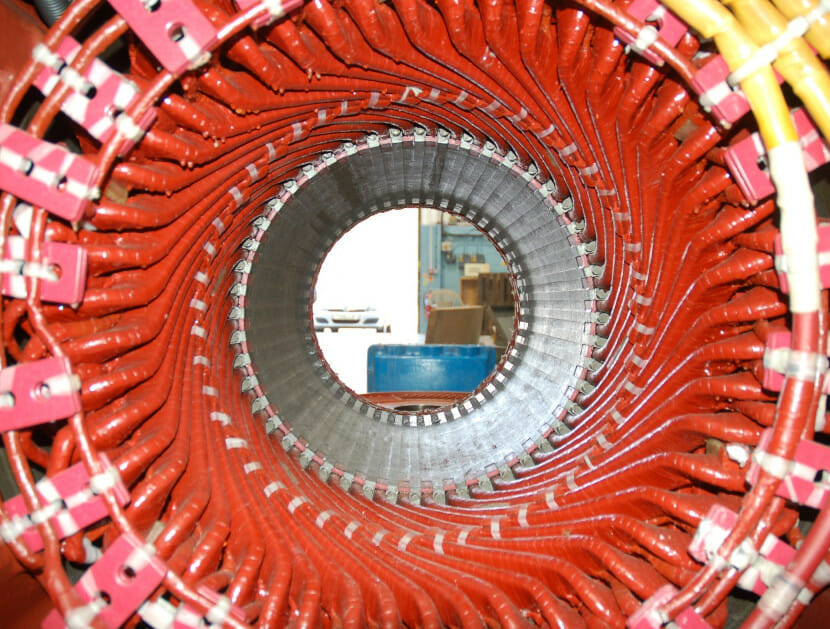

In conventional thermal power plants, traditional and common fuel sources are used to generate steam by heating water in order to drive a turbine, so to drive a generator to produce electricity.

Download our latest Brochure

Why Hawkins?

Hawkins is an industry leader with proven expertise and practical experience, married with a real awareness of our clients’ needs.

Rapid Response

- 24/7 availability

- Early site visit

- Prompt reporting

Quality Service

- A specialist team of forensic engineers and scientists

- Proven expertise and practical experience together with a rigorous peer review system

Breadth & Depth

- Over 150 impartial experts across an international network of offices

- Over 70 different areas of specialism

Commercial Awareness

- A range of services to suit your needs

- Combining successful outcomes with cost sensitivity

FEEDBACK FOR THE POWER & ENERGY TEAM

“We prefer Hawkins due to their international reputation and their experience in handling power plant claims.”