Wind Turbines: Risks & Failures

With increased demand for clean renewable energy wind turbines are growing in numbers, size and capacity. In this webinar, Amir will look at failures associated with wind turbines.

Divyeruthra Muniandy

Divyeruthra holds a first-class Mechanical Engineering degree with accolades from University Technology Petronas. Divye worked as a Material and Mechanical Integrity Engineer at Exxonmobil before joining Hawkins in 2023. Her Divye’s expertise lies within the domain of integrity management, material degradation, process degradation, troubleshooting, inspection, and maintenance in the oil and gas industry.

Sam A’Court

Sam has wealth of hands-on experience in the design, operation, maintenance, and modification of a wide range of process, utility, and safety systems, encompassing separation, heat exchange, produced water treatment, relief systems, and gas dehydration.

Bristol Series – Corrosion in the Power Industry

Giuseppe will focus on two widespread corrosion mechanisms that routinely lead to large BI claims in the power industry: Corrosion Under Insulation, and Microbiologically Induced Corrosion. He will discuss what causes these degradation mechanisms, as well as how to recognise and prevent them.

Domestic Heating Oil: Where, Why & How it Escapes

Patrick will look at the various ways in which domestic heating oil can escape into the environment and what should be done to prevent these leaks.

Materials Series – The Effects of Hydrogen on Materials Properties

Lin introduces the basic characteristics of hydrogen, the current trend for its applications, its effects on materials, and some recent examples of materials failures in the context of insurance claims.

Materials Series – Failures Encountered in Aeroderivative Gas Turbines

Stephen gives insight into what an aero-derivative is, as well as their benefits and disadvantages. He also discusses RCA methodology

and damage mechanisms encountered.

Stephen Rowbotham

Stephen is enthusiastic about providing solutions to issues faced by clients in the changing business environment and the goal of achieving net zero power generation.

Amir Hajdaei

Amir is an experienced materials engineering with experience in dealing with wide range of material such as metals and ceramics and in depth knowledge of fibre reinforced composites and polymers.

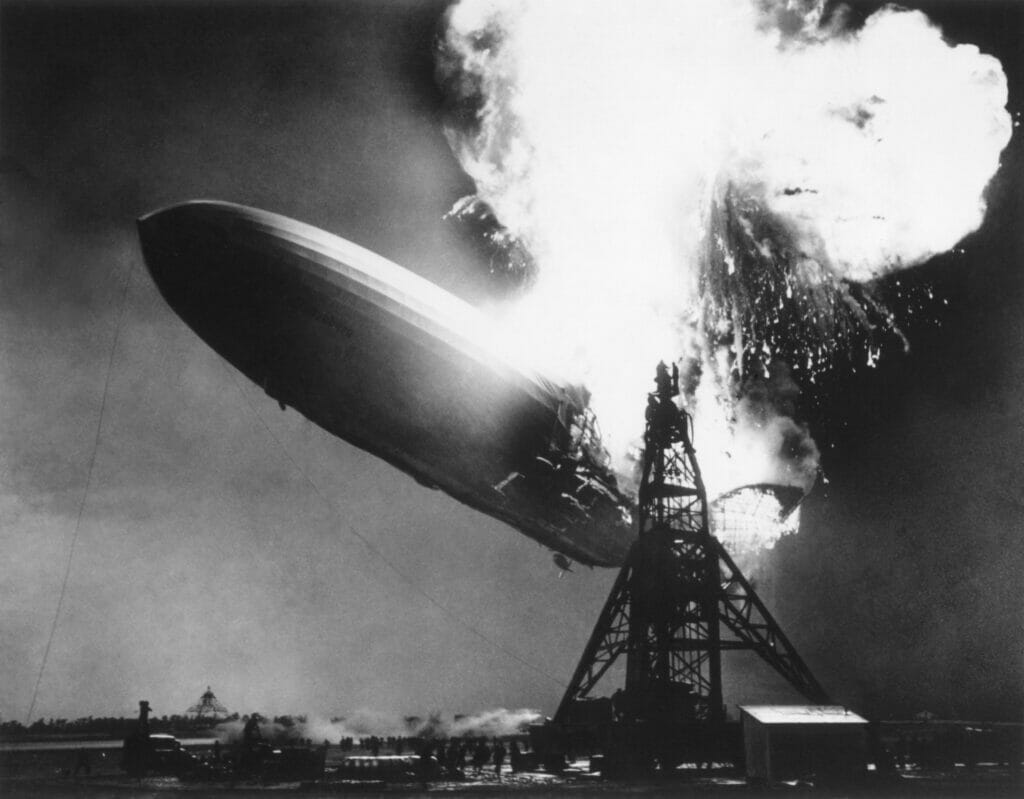

Glasgow series – BLEVE’S: The Hidden Dangers of Back Boilers

The hidden dangers of back boilers: Outlining the risks with domestic back boilers, and incorrect decommissioning can result in catastrophic damage

Italiano

Italiano