From Past to the Present – Ballasted Railway Track

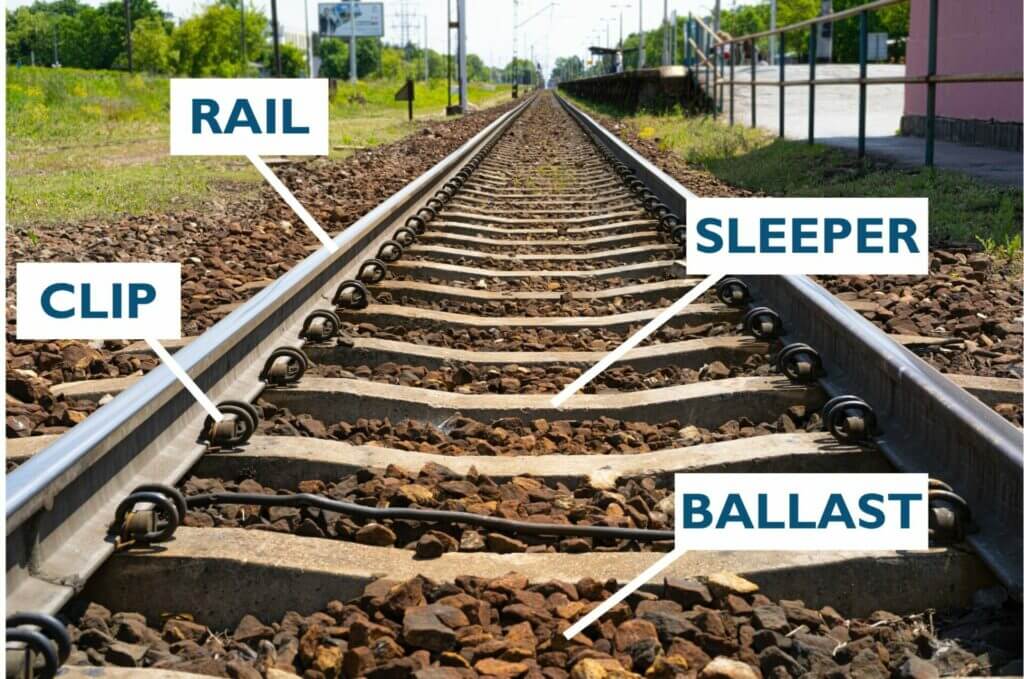

The basics of traditional railway track have not changed much in over 150 years. Rails are fixed to sleepers, which are then kept in place by ballast (crushed rock). The materials have been updated, with timber sleepers more recently replaced by concrete and steel, or even plastic composites. Fixings have also changed, with spring clips replacing nails or spikes. However, the general arrangement remains the same.

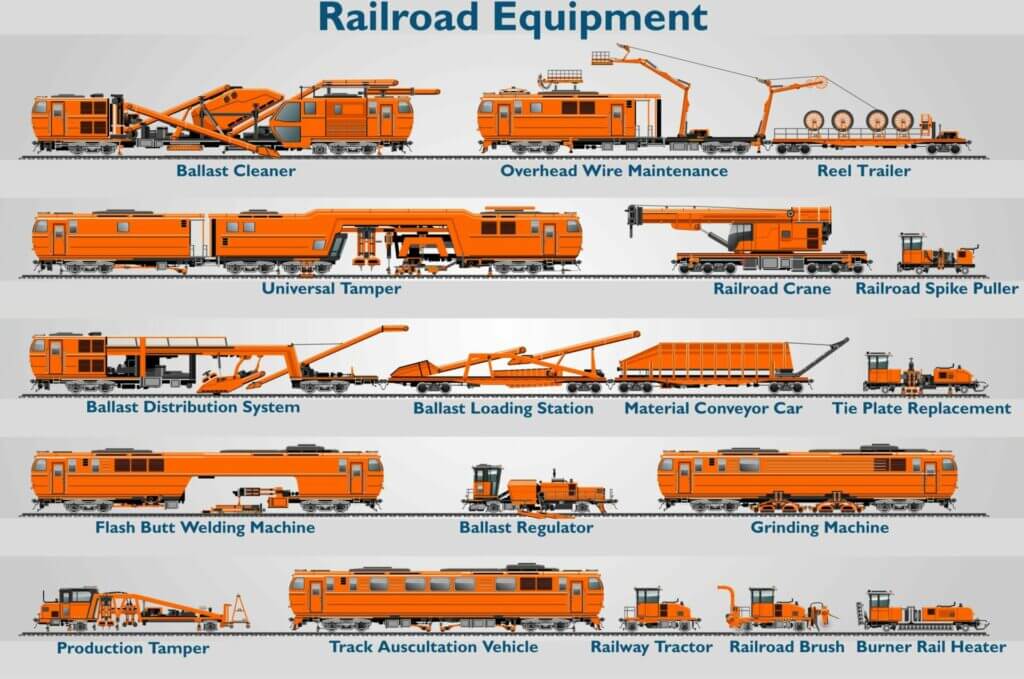

This system has its advantages. The design, performance and maintenance are all well understood, it allows for minor alterations to be made to the position of the track, and it is relatively cheap to install. There is also a large and competitive market, offering a wide range of highly efficient machinery for installation and maintenance.

However, this approach is not suitable for all situations. Specific requirements for different locations can often call for a reduced thickness or lighter weight track structure, for example in tunnels or on bridges. Trams, or other rail systems sharing space with rubber wheeled vehicles need a smooth surface that a ballasted track system cannot provide. More recently the push towards higher train speeds and more frequent services, along with higher maintenance costs is also driving the search for alternatives.

More Recent Developments – Ballastless or Slab Track

History

One approach which has been used over the years, and is becoming increasingly common, is “ballastless” or “slab” track, where the rail is fixed to a structure or “slab”. The forerunners of modern slab systems were first experimented with in the 1960s and 1970s in Japan and Germany.

In the UK, High Speed 2 (HS2) will be entirely slab track, whereas Crossrail (The Elizabeth Line) used various forms in its tunnel sections. Electrification projects across Network Rail use slab track to allow reduced clearances in tunnels and bridges for electrification “track lowers”. A number of light rail and metro projects make significant use of the technology. Globally, the growth in high-speed rail has contributed to large increases in the installed length of slab track, particularly in China, along with large light rail developments such as those in Paris, Melbourne, Tel Aviv and Riyadh.

Benefits

As the rails are fixed to the solid structure (normally concrete), the track holds its position better than that on ballast, which moves and settles under load. This is helpful for high-speed applications which require very tightly controlled track geometry. It is also beneficial in situations where there is a small clearance between the train and a structure such as a tunnel, or bridge, and any movement of the track could reduce the clearance to an unsafe distance. The precise and durable track geometry also reduces ground vibration and airborne noise, a key requirement in urban rail projects and where the impact of a more frequent service on nearby residents needs to be managed. Specific types of slab track, where the rail head is flush with the surrounding ground, are necessary for track routes also used by road vehicles, such as street running tramways, level crossings, or intermodal freight yards.

The durability of the slab track also reduces required maintenance. Firstly, ballasted track moves and migrates, requiring periodic realignment through “tamping”, the process of moving rails and sleepers back into place and recompacting the ballast. This is not required in slab track as it is fixed in position. Ballast, and to some extent sleepers, also deteriorate through attrition as a result of the cyclic loading, movement, and tamping. Ballast can also become contaminated with fine material from its own breakdown, or from other sources. This material reduces the ability of the stones that form it to lock together and hold position. As a result, ballast and other components need to be replaced every 15–30 years, depending on traffic levels and track geometry.

Slab track installations are generally designed to last at least 60 years, with limited maintenance of the structural elements. This can reduce the whole life cost of slab track below that of ballasted installations, despite a much higher initial capital cost.

Challenges

Slab track installations are not without their issues. Some early iterations, which involved standard timber sleepers cast into concrete, or slabs with rails resting directly on their concrete surface have not stood the test of time. The very stiff support resulted in high concentrated forces being applied to the slabs under wheel loads, and consequent deterioration.

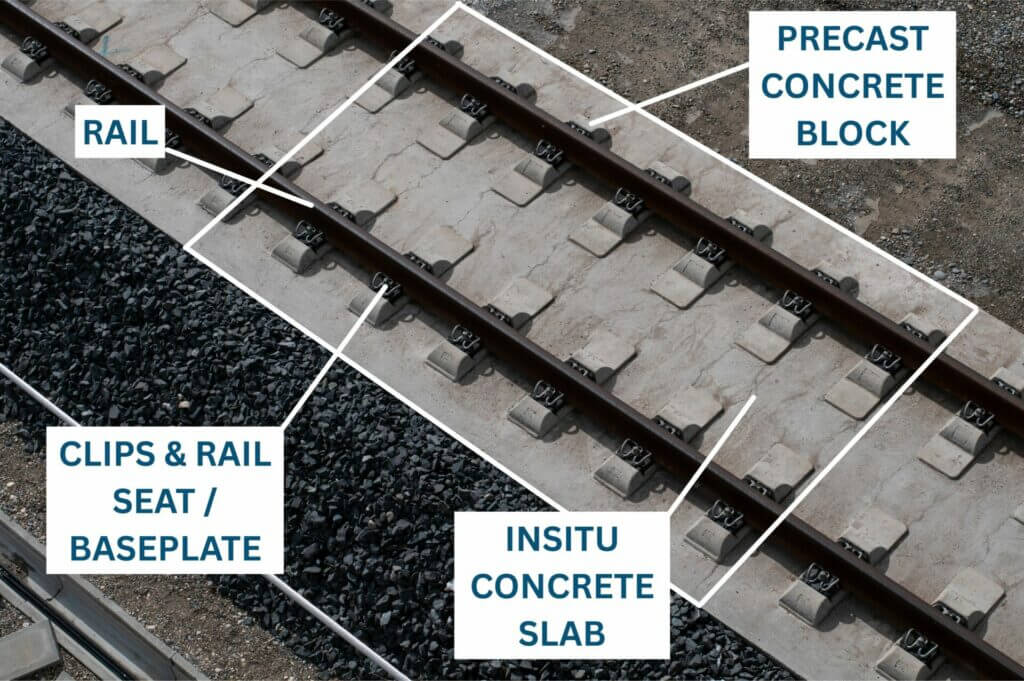

Modern slab track systems have dealt with some of these issues by using resilient components to allow some movement of the rail. This distributes the wheel loads over more supports, which reduces peak forces in the slabs and can reduce ground borne vibration from train movements. Prefabrication of components using precast concrete blocks or panels with integrated rail fixings is now widespread. These can be installed quickly and often have better manufacturing quality control than in-situ construction, providing a more precise and longer lasting track.

Slab track also requires much more stable foundations than ballasted track. During tamping, minor settlement or subsidence of a ballasted formation can be accommodated by lifting the track and adding more ballast. With slab track there is limited, if any, vertical adjustability, meaning the formation must have sufficient bearing capacity to guarantee no settlement for the life of the slab track. When constructing completely new railway lines on modern designed earthworks this is not usually an issue, but where slab track is being installed on existing infrastructure this can be costly and difficult to ensure.

The growing complexity of the design and installation of modern systems brings other issues. Most are proprietary products, with a limited pool of suitable designers and installers, restricting competition in tenders. In other cases, complex installations have unforeseen interactions with surrounding structures, requiring design or installation adaptations, or even costly post-construction alterations. Limited designer experience, a lack of understanding from clients or contractor unfamiliarity can all result in issues with the installation and operation of slab track systems. In some cases, a lack of maintainer familiarity, combined with the idea of “maintenance free” slab track, has meant repairable deterioration has been allowed to grow in severity until wholesale replacement is the only option.

The Future

A widespread move to ballastless track will be a significant change to the way the railway is constructed and maintained. This would bring significant challenges for the railway industry. The pure technical complexity is significant by itself. The design, construction and maintenance of slab track requires a wide range of skills and expertise which may not have been required or retained previously in railway track focussed organisations.

The large lengths of track slab to be designed and installed in the coming years in the UK, particularly for HS2, also brings its own issues. With a limited pool of experienced designers and installers, combined with a developing supply chain, there is the potential for issues meeting the required production rates and quantities.UK specific requirements mean that overseas experience may not be entirely applicable, therefore importing resources may not immediately resolve this issue. Both of these issues could affect quality, productivity, or costs in ways that companies may not foresee, with contractual or commercial consequences.

The move to ballastless track also involves an increased involvement of manufacturers and their products, compared to ballast. In turn, increasing the reliance on the product performance, and manufacturers’ liability if and when products fail, potentially many years after installation. These challenges alter the technical and commercial environment around the railway industry and potentially alter the risk exposure of companies involved in it, as well as the nature and frequency of contractual issues.

Summary

- The change is coming; ballastless tracks are likely to become more widespread.

- The drivers away from ballast, and towards ballastless, are only going to increase in power over time.

- This change will alter the commercial and technical environment around railway construction and maintenance.

- This will have potential impacts on client, designers and contractors risk exposure, and the nature and frequency of contractual issues.

About The Author

Thomas is a Chartered Engineer and a Member of the Institution of Civil Engineers. Since joining Hawkins in 2023 he has investigated failures of buildings, houses and structures as a result of wind, flooding, and accidental damage. He previously worked principally within the railway industry, latterly specialising in the inspection, diagnosis, design and installation of slab track. His work included the design and management of the design of ballastless railway track systems, as well as the planning and management of their construction. This included managing multi-disciplinary design teams and letting and managing subcontract design. Thomas worked on a significant number of projects investigating existing failed ballastless track systems, to identify the root cause of failure, and to design remedial or replacement works.

If you have an engineering or rail related query and need the help of Thomas or another Hawkins expert, please contact us for a free consultation.

Italiano

Italiano