Chiller systems are a vital component of modern cooling infrastructure, ensuring efficient climate control in various industries, from commercial buildings to data centres. However, when a chiller fails, the financial and operational impact can be substantial. According to a 2022 report from the U.S. Department of Energy, heating, ventilation, and air conditioning (HVAC) failures, including chillers, account for approximately 40% of unscheduled maintenance costs in commercial facilities. Mechanical failures are rarely isolated incidents; they are often symptomatic of underlying inefficiencies that accumulate over time. Proactively identifying and addressing these issues is key to maintaining system performance and reliability. In the sections that follow, we explore some of the common failure points that can compromise chiller system integrity and efficiency.

Compressor Failures: A Silent Threat to System Integrity

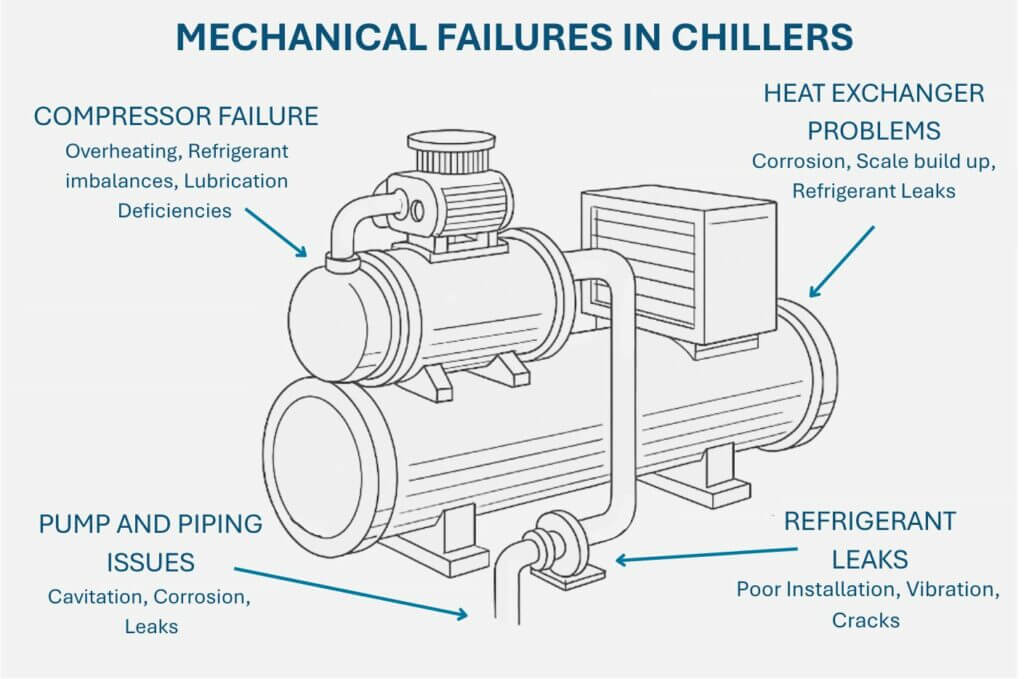

The compressor is at the heart of every chiller system, responsible for circulating refrigerant and facilitating heat exchange. According to data published in 2021 by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), compressor failures account for up to 38% of all chiller system breakdowns. Failures within this component can be attributed to several factors, including overheating, inadequate lubrication, or refrigerant imbalances. Motor burnout, often caused by voltage imbalance or thermal overload, is responsible for over 20% of compressor electrical failures. Early warning signs such as a 10-15% increase in energy consumption or temperature deviations of 2-5°C from setpoints should never be ignored, as they often precede major compressor damage.

Heat Exchanger Degradation: A Hidden Efficiency Loss

Heat exchangers are integral to a chiller’s thermal transfer process, yet their functionality can decline due to corrosion, fouling, and refrigerant leakage. These issues directly impact heat transfer efficiency, forcing the system to operate at higher energy levels to compensate for performance deficiencies. Fouling and scaling can reduce heat exchanger efficiency by 10-30%, depending on the fouling material and thickness. Fouling deposits on heat exchanger surfaces further restrict thermal conductivity, driving up operational costs. A 0.5 mm thick fouling layer can increase energy consumption by up to 20%. While the effects of degradation may not be immediately noticeable, cumulative damage significantly increases the risk of mechanical failure and operating costs over time.

Circulatory Disruptions: Pump & Piping Vulnerabilities

Fluid circulation within a chiller system depends on a network of pumps and pipelines, where even minor disruptions can compromise efficiency. Cavitation, caused by vapor bubble formation, can reduce pump efficiency by up to 40% and significantly shorten pump lifespan. Vapor bubbles can also lead to severe internal damage, while corroded or obstructed piping restricts flow rates, leading to reductions of up to 25% and impacting cooling performance.

The Impact of Refrigerant Leaks on System Performance

A well-maintained refrigerant system is fundamental to chiller efficiency, yet leaks caused by component wear, vibration-induced cracking, or improper installation can severely impact cooling capabilities. Even a 10% reduction in refrigerant charge can diminish heat transfer and lead to a 15% drop in system efficiency. Beyond the financial strain, refrigerant leaks pose environmental concerns and regulatory compliance challenges. Moreover, refrigerant losses significantly contribute to global warming. Hydrofluorocarbon (HFC) based refrigerants have Global Warming Potentials (GWPs) ranging from 1,300 to over 3,900. This means that, over a 100-year period, these gases can trap 1,300 to nearly 4,000 times more heat in the atmosphere than the same amount of carbon dioxide, significantly contributing to climate change.

Operational and Financial Implications of Chiller Breakdowns

The consequences of chiller failures extend beyond equipment replacement costs. Industries reliant on climate-controlled environments face significant operational disruptions. These include healthcare, manufacturing, and data centres, all of which face significant operational disruptions when cooling systems malfunction. For instance, in data centres, cooling system downtime can cost hundreds of thousands to several million USD per day, depending on the size, design, and technology in use. These costs stem not only from the immediate loss of service and potential data corruption, but also from cascading effects on business continuity and regulatory compliance. In high-density environments, where servers generate substantial heat, even a few minutes of cooling failure can cause significant hardware damage.

Unplanned downtime introduces financial liabilities, including emergency maintenance expenses and productivity losses. Furthermore, compromised system components pose safety risks, overheated electrical systems increase fire hazards, while refrigerant leaks present health concerns for occupants.

Expert Analysis: The Role of Mechanical Specialists

Diagnosing chiller failures requires more than just identifying damaged components; it requires a thorough understanding of the root causes behind malfunctions. Mechanical specialists provide invaluable assessments, determining whether failures stem from improper maintenance, design defects, or operational mismanagement. These expert evaluations assist businesses assign liability, whether to manufacturers, installation teams, or maintenance personnel, and also provide actionable insights to improve long-term performance and prevent recurring failures. According to the International Facility Management Association (IFMA), organisations that employ predictive diagnostics experience 30-40% fewer equipment failures compared to those relying solely on reactive maintenance.

Recovery Strategies and Risk Mitigation

A mechanical failure does not always equate to complete financial loss. Businesses may explore recovery options such as insurance claims or legal recourse if system malfunctions can be attributed to negligence or defective equipment. Additionally, implementing predictive monitoring systems can reduce unplanned downtime by up to 50%, enabling businesses to detect performance inefficiencies before they escalate into major failures. Investing in risk mitigation strategies ensures operational resilience while minimising costly disruptions.

Prioritising Proactive Maintenance for Long-Term Reliability

While mechanical failures can result in significant setbacks, preventive maintenance remains the most effective solution for extending chiller lifespan and reducing unexpected breakdowns. Routine inspections, refrigerant system monitoring, and timely repairs all contribute to optimal system performance. Given that chiller systems operate through interdependent components, neglecting any individual element can lead to widespread inefficiencies. Strategic maintenance provides consistent cooling capacity, operational stability, and cost savings over the long term. Well-maintained chillers can last 20–25 years, whereas neglected systems may fail after just 10–12 years. This approach not only maximises cooling capacity and operational stability but also yields annual energy savings of 15-20%.

Conclusion: Prevention Over Repair

Chiller malfunctions can lead to extensive financial and operational consequences, impacting productivity, budgets, and safety. Understanding failure mechanisms and implementing proactive maintenance strategies are essential for ensuring uninterrupted performance. By investing in expert diagnostics and preventive interventions, businesses can safeguard their cooling infrastructure and avoid costly repair scenarios. For chiller systems, early intervention is consistently more cost-effective than reactive repairs.

About the Author

Albert Law is a Chartered Mechanical Engineer and Associate at Hawkins, based in our Hong Kong office. With over a decade of experience in mechanical, electrical, and plumbing (MEP) design and project management, Albert has worked on high-profile projects across Asia and the Middle East, including railway systems, data centres, and commercial buildings. He holds a Master’s degree in Building Services Engineering and is a member of several professional bodies, including the Institution of Mechanical Engineers (IMechE), the Chartered Institution of Building Services Engineers (CIBSE), and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). If you have an incident you would like Albert to investigate, please get in touch.

Italiano

Italiano