Bamboo scaffolding, alongside neon signs and red taxis, has long been a defining feature of Hong Kong’s urban landscape. But like many cultural icons, it is now facing a quiet retreat. In a move driven by safety concerns, The Government of Hong Kong is beginning to phase out bamboo scaffolding in public construction projects, marking a significant shift in the city’s construction practices.

A Policy Pivot Toward Metal

On the 17 March 2025, the Development Bureau of Hong Kong issued a circular memo titled “Adopting of Metal Scaffolds in Public Works”. This document outlines a new requirement that from 21 March 2025, all public works tenders must specify the use of metal scaffolding. Bamboo may only be used in exceptional cases, and only with detailed justification.

The Bureau cited bamboo’s “intrinsic weaknesses,” including inconsistent mechanical properties, susceptibility to deterioration, and high combustibility, as key reasons for the change. Additionally, the Bureau is cognisant of the wide adoption of metal scaffolding in Mainland China and other advanced economies.

The Case for Bamboo

Despite its drawbacks, Hong Kong has historically favoured bamboo scaffolding for several compelling reasons. It is:

- Lightweight and flexible

- Cost-effective

- Easier to handle, especially for aged labourers

- Quick to erect and dismantle

- Adaptable to complex building geometries

These advantages have contributed to bamboo scaffolding becoming a staple of the city’s construction industry for decades. However, safety concerns have persisted.

Putlogs: A Common Source of Failure

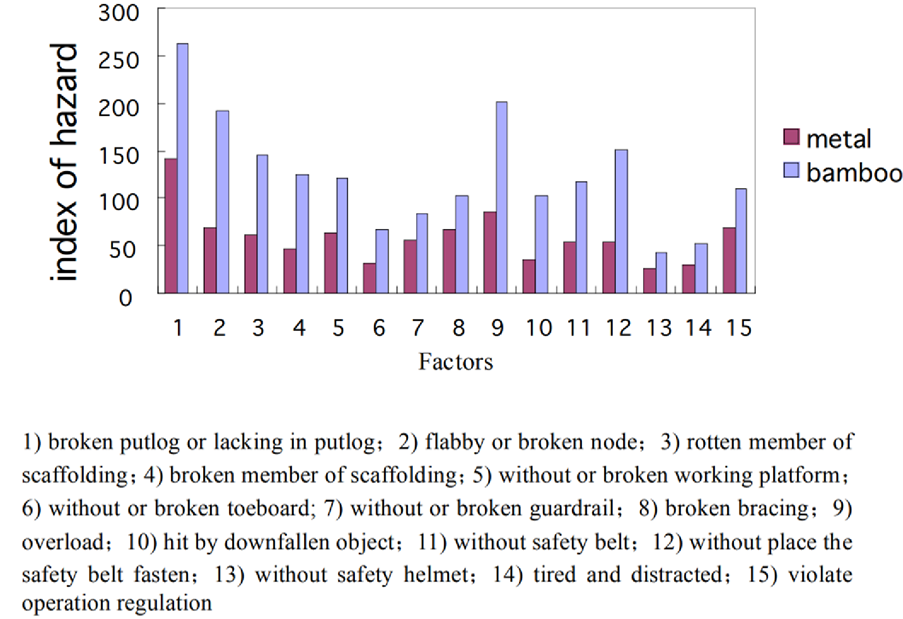

A 2004 study by Tsinghua University titled “Comparative Study of Safety and Application of Bamboo and Metal Scaffolding in Hong Kong”[1] found that the most significant hazard in both systems was the failure or absence of putlogs – horizontal members that tie scaffolding to the building structure. An excerpt from the paper showing the hazards associated with both types of scaffolding can be seen below.

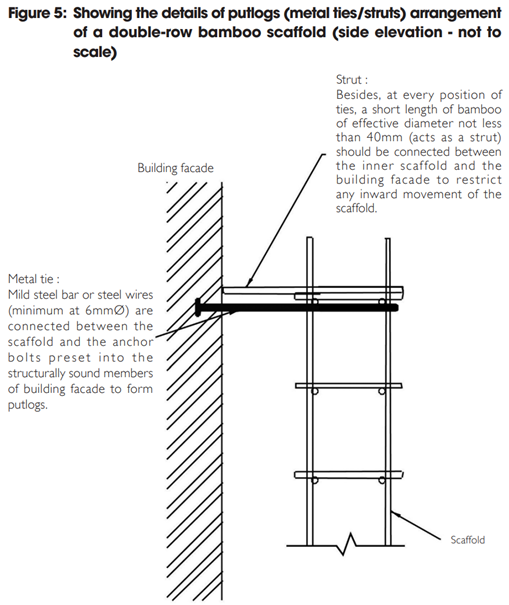

Interestingly, Hong Kong’s safety codes impose stricter requirements on bamboo scaffolding putlogs than on metal ones. Bamboo scaffolds (under 100m in height from ground) must have putlog ties spaced no more than 3 meters horizontally and 6.3 meters vertically (equivalent to one per 18.9m2), with each tie capable of withstanding 7kN[2]. In contrast, metal scaffolds require only one tie per 25m², with a lower strength threshold of 6.25kN[3].

This raises a critical question: if bamboo scaffolding is held to higher standards with regards to putlogs, why is it perceived as less safe?

The Real Risk: Lack of Oversight

A recent scaffolding collapse involving 20 workers revealed the true issue: inadequate professional oversight. Investigators found that the metal ties used for the bamboo putlogs were as thin as 1.06mm – far below the required 6.00mm[4]. The collapse was not due to the use of bamboo itself, but to unauthorised modifications and a lack of professional design and supervision. A government safety officer emphasised the need for scaffolding to be professionally designed and approved. The Chairman of the Construction Industry Council echoed this, calling for better coordination among engineers, supervisors, and qualified personnel to prevent such failures[4].

Looking Ahead: A Role for Expertise

While the shift to metal scaffolding may reduce some material-related risks, it does not reduce the need for professional oversight. Whether bamboo or metal, scaffolding systems must be properly designed, installed, and maintained.

The phasing out of bamboo scaffolding in public works marks the end of an era in Hong Kong’s construction history. Although the decision is rooted in legitimate material safety concerns, it also reflects a broader shift toward modernisation and regulatory rigour. As this transition unfolds, it is essential to recognise that safety is not solely a matter of materials and regulations – it is also a matter of professional expertise.

How can Hawkins Help?

At Hawkins, our chartered civil and structural engineers bring deep industry experience in design consultancy, site supervision, and forensic investigation. We offer guidance to the construction industry, helping define and develop working procedures and practices that reduce the risk of incidents and lead to safer outcomes. Our Hong Kong team has investigated a wide range of incidents, including, crane and material hoist collapses, concrete spalling, slope failures, and structural damage from vehicle collisions. Our goal is to provide clarity, accountability, and actionable insights that help prevent future incidences.

About the Author

Patrick is a Chartered Structural Engineer based in our Hong Kong office. He has many years of experience in the construction industry and has worked for both contractors and consultants on temporary and permanent structural works. He has designed temporary supporting structures for both metal and bamboo scaffolds. As a resident site engineer, he has also monitored scaffold construction safety and ensured that temporary working platforms are adequate to support all intended loads.

Patrick joined Hawkins as an associate in 2024 to expand the forensic structural engineering capabilities of Hawkins in the Greater China and Asia region.

If you would like to discuss any incident—whether related to the built environment or any of the many other scientific and engineering disciplines Hawkins supports its clients with worldwide, please get in touch.

References:

[1] Fang, DP, Wu, SH, Wong, KW & Shen, Q 2004, A comparative study on safety use of bamboo and metal scaffolding in Hong Kong. in Construction safety management systems. Spon Press, pp. 373-386.

[2] Hong Kong Labour Department 2024, Code of Practice for Bamboo Scaffolding Safety, Fifth Edition.

[3] Hong Kong Labour Department 2013, Code of Practice for Metal Scaffolding Safety, Second Edition.

[4] Hong Kong Construction Industry Council 13 February 2025, Life First Walk the Talk Webinar – Bamboo Scaffolding Safety and Code of Practice.