Racking Collapses & Failures

Modern warehouse environments are increasingly reliant on high-rise racking systems to maximise storage capacity and improve operational efficiency. However, these structures can be vulnerable to collapse due to a range of design, installation, and operational factors.

At Hawkins, our forensic engineers have extensive experience in investigating racking incidents worldwide, including racking collapses, operational failures, and personal injuries linked to racking systems and manual handling. From isolated failures to catastrophic, full-warehouse collapses, we combine engineering expertise with practical knowledge of warehouse operations, to deliver clear, evidence-based conclusions.

We provide expert analysis to determine the root cause of failure, assess liability, and support effective recovery and prevention strategies.

WHY APPOINT A FORENSIC INVESTIGATOR?

Modern racking systems can have their structural integrity compromised by a range of factors, including design issues, installation errors, improper use and inadequate maintenance. Hawkins can identify the point of origin of the failure and determine whether it arose from design flaws, operational issues, or external impacts.

We have in-depth knowledge of the relevant standards, regulations and best practice that should be followed

We review working practices, designs and installations to identify areas of high risk

We offer guidance and help you define and develop robust procedures and practices to reduce the likelihood of incidents occurring

We provide the clarity you need to understand why an incident occurred and to support informed repudiation or recovery decisions

With extensive engineering experience and detailed knowledge of all racking system types, our experts can investigate every aspect of a racking failure

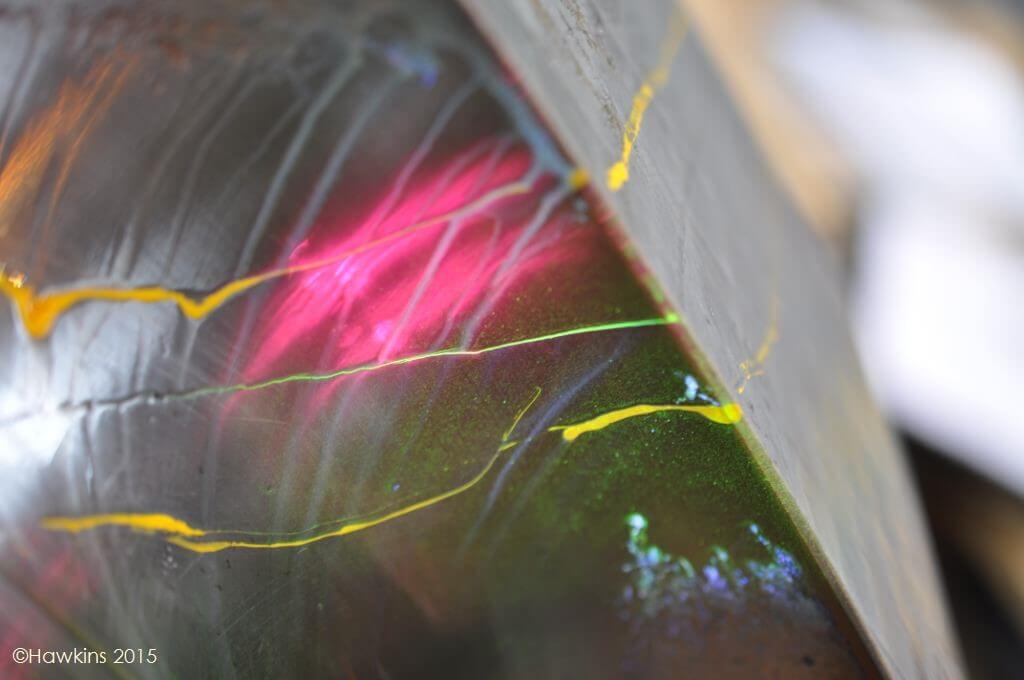

Our laboratories are equipped with high-powered optical microscopes for examination of metal samples

- Where samples cannot be removed for laboratory analysis (such as steel in fixed buildings/structures), our metallurgists can do on-site metallographic preparation of replicas so that the microstructure can be examined under laboratory microscopes

We will help you to determine if an incident could have been prevented

We support subrogation recovery claims

We help you assess where legal responsibilities and liabilities lie

We assist in defending wrongful claims

We produce reports that are suitable for Court and litigation

We provide consultancy advice to help prevent similar events from occurring in the future

Where risks cannot be eliminated entirely, we advise on steps to mitigate them and reduce potential damage

We advise on appropriate servicing, maintenance and repair regimes

We have detailed knowledge of policy cover, liability and warranties to assist effective decision making

Examples of Typical cases

The list below provides just a few examples of the type of incidents that we have investigated.

- Inadequate design or insufficient safety margins of racking systems

- Incorrect installation including poor anchoring or leaning structures

- Overloading or uneven weight distribution

- Impacts from mechanical handling equipment (MHE), such as forklift collisions

- Floor slab failure or subsidence in a warehouse

- Environmental degradation, including corrosion or chemical exposure

- Pallet failure or damaged goods

- Poor or incorrect pallet positioning

- Incorrect use of manual handling equipment

- Warehouse fires triggered by racking collapse

- Contamination resulting from goods involved in a collapse

- Damage to a building following a racking collapse

- Product damage and product recovery

- Material failure in racking components

- Unapproved modifications or reconfiguration of the racking layout

If you would like more information or to discuss a specific incident, you can contact us for a free consultation.

HOW DOES HAWKINS INVESTIGATE RACKING COLLAPSES?

1

Consultation

We begin with a discussion to understand your needs and review available information such as service records, witness accounts, photographs and CCTV. At this stage, we can also provide an estimated cost for the investigation.

2

Inspection

With your agreement, we carry out a site visit to examine the failure and its surrounding context. This includes collecting evidence, reviewing documentation, and retaining faulty components for laboratory analysis. Where facts are unclear, we provide informed, professional opinions based on our expertise.

3

Conclusion

We present our findings and prepare a detailed report outlining our investigation, conclusions, and recommendations. Our reports are CPR-compliant and suitable for both claimant and defendant instructions.

SPEAK TO ONE OF OUR EXPERTS

Related areas of expertise

Civil & Structural Engineering

Whether it is a subsiding foundation, a collapsing structure or a flooding drainage system, it can be hard to understand at first glance what part of a large system has gone wrong.

Building Defects & Regulations

A building defect can be described as any deficiency or shortcoming in the performance or function of a building that prevents it from satisfying statutory or user requirements. Building defects fall broadly into three categories:

Metallurgy

Losses involving metallurgical failures occur in a wide range of industrial and domestic environments and can lead to high value claims or even loss of life.