Vehicle Examinations

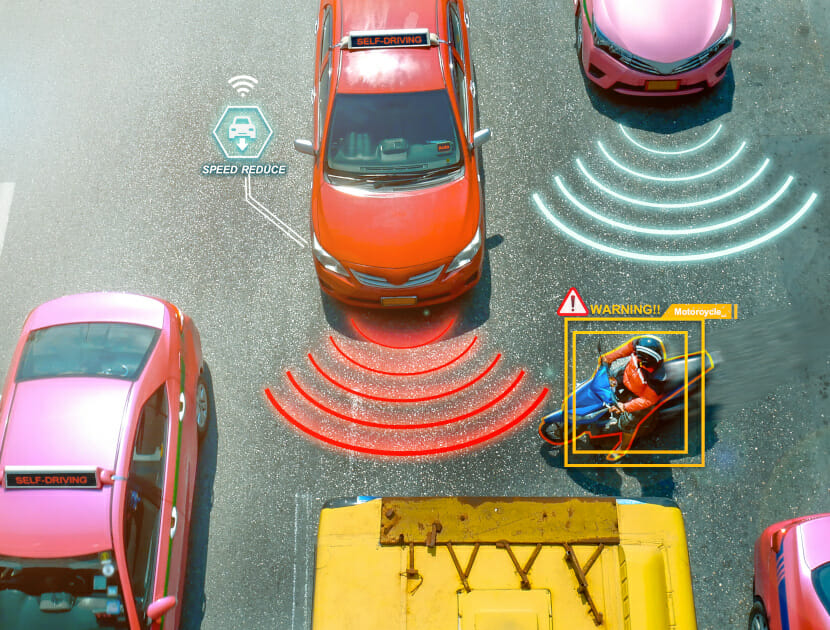

Whether the case involves a car, bus, heavy goods vehicle, motorcycle, farming equipment, or a bicycle, Hawkins’ engineers consider various vehicle attributes during an examination, such as: patterns of damage, occupant restraints, vehicle condition, vehicle defects, tyre performance, and vehicle stability. It is also becoming more common for vehicles to carry recoverable collision data from the EDR (Event Data Recorder) aka the black box.

We always prefer to examine damaged vehicles as soon as possible. Generally, this means whilst still under Police retention where only a visual examination might be permitted. But it can be very important to see a vehicle before the physical evidence deteriorates. Furthermore, if it is a multi-vehicle collision and those vehicles have been retained by Police at the same location, it can be an excellent opportunity to inspect and consider the corresponding patterns of damage between those vehicles.

Delayed examination after release by the Police risks the vehicles being repaired or destroyed before valuable information is recovered. Whilst third party vehicles can sometimes be inspected later, it requires collaboration with other interested parties for access to be authorised which can lead to a delay in investigation.

We can also make a preliminary examination of a scene, hopefully whilst some physical evidence can still be seen and before any changes are made to the road layout or even the grass of a verge is mowed. It is common for vehicles to be retained by Police within the general region of the collision, and so attending the scene and capturing valuable evidence can be performed alongside the vehicle examinations.

Once the Police plans, photographs, laser scans, and other information become available, we can move on to a detailed analysis. You can read more on this in our Collision Reconstruction page.

Several of our experts are engaged exclusively or primarily in road traffic accident analysis and bring a combination of both academic research and industry knowledge.

What do we Look for During a Vehicle Examination?

Whilst every investigation is different, there are several questions that are often asked when we are instructed to examine a vehicle, examples include:

- What was the extent of the damage?

- What was the speed of a vehicle before a collision?

- Was a person wearing a seatbelt?

- Did the supplemental restraint systems function properly?

- What lights were illuminated?

- Were there any defects with the vehicle that could have caused or contributed to the collision?

- Can we recover any data from the vehicle?

There are well-established ‘classical’ methods which have been used for many years to help answer these questions. However, some are becoming less useful, generally as a result of technical developments in vehicles, whilst some newer techniques are becoming increasingly important.

Hawkins keeps at the forefront of technology and research to ensure that we keep abreast of these developments, see our pages on pages on Event Data Recorders and 3D laser scanning.

Extent of Damage

Consideration of the damage caused can give an indication of the severity and the direction of the primary impacts.

From close inspection of the damaged areas, we can assess how the damage was caused and look for evidential transfer. Damage might have been caused from:

- solid objects such as other vehicles where there might be coloured paint transfer;

- structures such as walls, where there might be brick dust;

- roadside furniture such as lamp posts which might leave characteristic columns of damage;

- or trees were bark or vegetation might be embedded in the vehicle.

In collisions involving pedestrians and cyclists we will also look for evidence of where and how they interacted with the vehicle, which might allow us to comment on the relative directions between the parties.

Extent of damage, particularly intrusion into the passenger compartment, can give an indication of expected injury severity of the occupants. We might choose to perform a 3D laser scan survey of the vehicle, so that accurate measurements of the vehicle and their damage caused can be made in a computer model, long after the vehicle has been disposed of.

Vehicle Speed

An approximation of collision speed can be made from the extent of the damage caused.

Speed can also be indicated on some types of present-day stepper-motor analogue instruments, where readings can freeze at the time electrical power was interrupted during a collision. The apparent reading can sometimes be quite different from the actual road speed, depending on the design of the instrument and the nature of the impact. At best it is only a supporting rather than primary measurement.

Seatbelt Use

Close inspection of seatbelts can reveal whether the occupants were correctly restrained and if an occupant’s decision not to wear a seatbelt might have contributed to their injuries.

It can be quite straightforward to see positive evidence that a seatbelt was in use, either from friction markings to the plastic parts on the buckle or transfer to the webbing. However, the absence of such marking does not necessarily mean the seatbelt was not in use and often in low-speed collisions, no marking might be caused. The collision event, and the directions of any impacts much all be considered.

Sometimes lack of seatbelt use is obvious and can be identified by a head impact from a front seat passenger into the inside of the windscreen or in the case of an unrestrained rear seat passenger, they might move forward and cause distortion to the front seat backrests. We still see many cases of unrestrained rear seat occupants!

Supplemental Restraint Systems

It is easy to determine if the supplemental restraint systems (airbags and seatbelt pre-tensioners) have deployed or not, but will not confirm whether the deployment criteria were met. For that we need to consider the damage caused and expected levels of speed change. We might also find our answer from interrogation of the EDR.

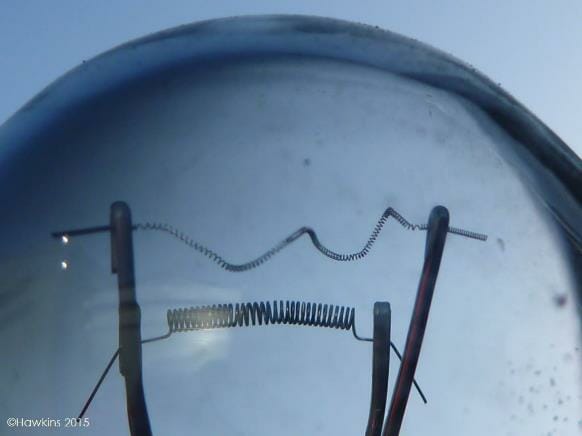

What Light Bulbs Were Illuminated?

Conventional inert gas filled light bulbs, introduced on cars more than 100 years ago, and tungsten-halogen bulbs, which date from the 1970s, both use coiled tungsten wire filaments. Tungsten has the property that at ordinary ambient temperatures it is relatively brittle and if exposed to a shock load, is likely to break. However, if a tungsten wire is hot, it becomes ductile so if exposed to the same shock the filament will tend to distort and often unravel, rather than simply break cleanly.

So, in this example clear indication that the moment of impact the brakes were not on, but the taillights were.

Inspection of the light bulbs can be particularly important when considering night-time collisions; was the driver using main or dipped beam? Did they even have their headlights on? Or in any collision where a turn signal should have been displayed.

Vehicle Defects

Probably the most asked question, were there any defects with the vehicle that could have caused or contributed to the collision?

During an examination will inspect all the primary mechanical systems, such as steering, brakes and suspension including the condition of the tyres. Whilst collision damage can sometimes make identification of a pre collision defect more difficult, our experience allows us to differentiate between the two.

Tyres are a critical feature since they are the point of contact between the vehicle and the road. Our engineers attend training at Michelin tyres headquarters, Stoke, for the weeklong tyre technical course so they are qualified to make detailed comment on tyre failures.

Can We Recover Any Data From The Vehicle?

See our Event Data Recorder page.

SPEAK TO ONE OF OUR EXPERTS

Principal Associate, Managing Director (Acoustics)

Email mePrincipal Associate

Email mePrincipal Associate

- Escapes of Water, Oil & Gas ,

- Composites ,

- Construction Injuries ,

- Falls from Height ,

- Noise & Vibration Injuries ,

- Lifting Operations ,

- Collision Reconstruction ,

- Marine Coating Failures ,

- Materials Failures Onboard Ships ,

- Materials, Chemistry & Biology ,

- Chemistry ,

- Concrete & Aggregates ,

- Contamination & Pollution ,

- Electronic Materials ,

- Fibres & Textiles ,

- Metallurgy ,

- Packaging ,

- Water ,

- Wood

Senior Acoustics Consultant

Email mePrincipal Associate

- Composites ,

- Glass & Ceramics ,

- Metallurgy ,

- Plastics/Polymers ,

- Escapes of Water, Oil & Gas ,

- Construction Injuries ,

- Falls from Height ,

- Marine Coating Failures ,

- Materials Failures Onboard Ships ,

- Materials, Chemistry & Biology ,

- Concrete & Aggregates ,

- Electronic Materials ,

- Fibres & Textiles ,

- Packaging ,

- Water ,

- Wood

Principal Associate

Email mePrincipal Associate

- Building Fires ,

- Escapes of Water, Oil & Gas ,

- Composites ,

- Construction Injuries ,

- Falls from Height ,

- Manual Handling ,

- Lifting Operations ,

- Power & Energy ,

- Gas Turbines ,

- Geothermal ,

- Hydro Power ,

- Marine Coating Failures ,

- Materials Failures Onboard Ships ,

- Materials, Chemistry & Biology ,

- Chemistry ,

- Electronic Materials ,

- Fibres & Textiles ,

- Packaging ,

- Wood

Marketing Manager

Email meGroup Financial Controller

Email meOperations Manager

Email meIT Manager

Email meHR Manager

Email meHSE & Facilities Manager

Email mePrincipal Associate

- Power & Energy ,

- Geothermal ,

- Generators ,

- Escapes of Water, Oil & Gas ,

- Marine Engineering ,

- Mechanical Engineering ,

- Composites ,

- Glass & Ceramics ,

- Metallurgy ,

- Plastics/Polymers ,

- Manual Handling ,

- Gas Turbines ,

- Hydro Power ,

- Marine Coating Failures ,

- Materials Failures Onboard Ships ,

- Materials, Chemistry & Biology ,

- Electronic Materials ,

- Fibres & Textiles ,

- Wood

Principal Associate

Email mePrincipal Acoustics Consultant

Email mePrincipal Acoustics Consultant

Email meRelated areas of expertise

Collision Reconstruction

Road traffic collisions (or accidents) are often traumatic incidents and litigation arising as a result is becoming more common as Court awards increase and injured parties become more aware of the compensation that might be available to them. Hawkins can provide detailed analysis of an incident and prepare forensic collision investigation and reconstruction reports suitable for use in Criminal or Civil Courts.

Highway Engineering

The condition of roads and highways, their drainage, layout or the routine maintenance of them is often blamed as being the cause of an accident or as having been a contributory factor. Sometimes this is true, but not always and when it is true, it is often necessary or helpful to determine to what degree.

Vehicle, Plant & Machinery Fires

Vehicle, Plant and Machinery share common operational systems such as internal combustion engines, hydraulic, cooling and lubrication systems, as well as electronic control systems to ensure safe operation of them.